|

tamar

Posts: 804

Registered: 5-1-1989

Location: Gouda

Member Is Offline

Mood: A new beginning

|

|

posted on 20-8-2018 at 20:30

|

|

|

2x6=? , 1/32 BMW M6 GT3/GTLM build to DiSCA Spec

BMW M6 GT3 / GT-LM

In 2016, the BMW M6 GT3 replaced the BMW Z4 GT3, which had been in action around the world since 2010. Since then, the BmW M6 GT3 has been the top

model in BMW Motorsport’s customer racing range. The car is powered by a 4.4-litre V8 engine with M TwinPower Turbo technology. The power train has

dry sump lubrication and generates up to 585 hp – with the whole car weighing less than 1,300 kilograms. The car won the Spa-Francorchamps 24 Hours

in its very first season. Other technical features are the transaxle drive concept, a sequential six-speed racing gearbox, and powerful motorsport

electronics. BMW Motorsport released an extensive Evo package for this car for 2018.

The GTLM version is nearly identical to the GT3. Most specific differences are GTE rule driven.

The GT3 variant features the same sized (rear) tires all around, while the GTLM — which is homologated for IMSA competition only — has a slightly

smaller tires on the front, per GTE rules (680 vs 710 mm).

The other difference in tires comes from the manufacturers themselves, as BMW Team RLL works with Michelin in GTLM and Continental Tire is the

exclusive provider for the IMSA GTD class (open for FIA GT3). There’s also a slight difference in aero between the cars, with the GT3 variant having

two front dive planes, compared to one on the GTLM. Also, the GTLM car does not have a decklid spoiler.

“Fundamentally, the GTLM is a little more efficient car,” O’Connell said. “Originally in the GT3 rules, they have a little bit more power than

GTLM overseas. But the cars are very close (in IMSA). The chassis are virtually identical. The basic frame of the car is the same. There’s just

little differences in clutch and some of the systems that are allowed.” (no ABS allowed for GTE)

Quite recently I was having a discussion about a new set of 1/32 slotracing rules. This rule set was to be open for GT3 cars from different makes.

In this discussion a respected and experienced slotracer brought forth the following argument:

"Nobody in his right mind will ever enter a Carrera (BMW M6) car in a major multi brand competition".

Off course I had to disagree with him, even though from his point of view he was absolutely right.

If such a set of rules were to proscribe "Stock bodies and chassis" all Carrera cars would have absolutely no chance what so ever.

They would not be moving chicanes, they would be the concrete guardrails for the Black Arrows, NSR, Scaleauto and Slot.it cars to crash into. Luckily

the rules my M6 will be build to give me plenty of room to take a stock Carrera and turn it into a competitive slot car.

Here are the dimensions of the 1/1 BMW M6

GT3/GTLM:

Length: 4.944 mm, Width 2.046 mm, Wheelbase 2.901 mm. Height 1.201 mm

Here are the dimensions scaled down to 1/32

Length: 154,50 mm Width:63,94 mm Wheelbase: 90,66 mm Height 37,81mm

And finally here are the dimensions of the Carrera M6 GT

Length: 155,00 mm Width:64,00 mm Wheelbase: 90,60 mm Height 39,00 mm

Build for competition...against peers

So far so good, the Carrera slot car is pretty damm good to scale. So what's the problem? Why did the respected slotracer deem the Carrera cars as so

"uncompetitive"? Well first of all one should know that if raced against its peers (as in other Carrera cars) the M6 is pretty good. Yes its a big

lump of a car, but along comes a long wheelbase to even out the performance against lets say a BMW Z4 or a Porsche 911 GT3 RS.

The same goes for the chassis, maybe not top notch compared to the "competition brands" but the chassis is straight & square, has steel axles with

brass bearings, nice wheels (plastic) and grippy tires.

Build for competition...DiSCA style Build for competition...DiSCA style

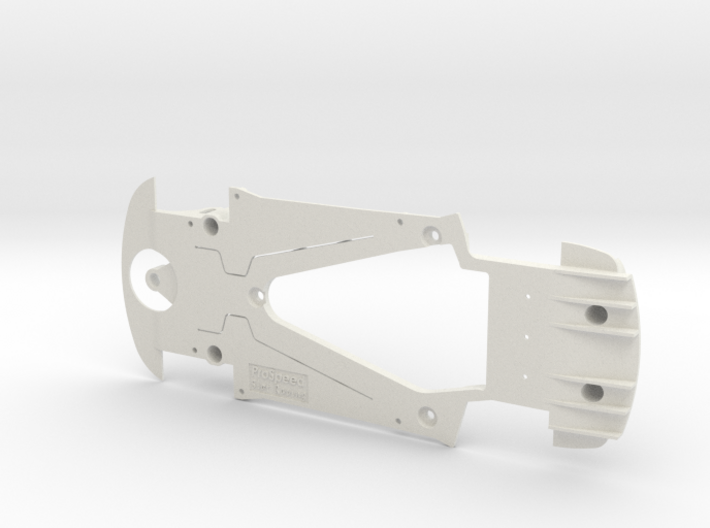

With the advent of 3D chassis that are now widely available, upgrading a Carrera, Scalex or Fly car with a "competition" orientated chassis has

become a much easier job...For the M6 I will use the ProSpeed chassis

designed by Stefan Nalbach (D). Its a straight swap over, the chassis I picked is suited for an NSR pod and will be loaded to the hilt with comp

parts.

Body mass

The main problem with getting a Carrera car on even footage with the "competition" is body mass.

Carrera cars are well detailed, well build, but very, very heavy. It almost looks like they also wanted to recreate scale weight.

BMW lists the M6 GT weight as less than 1300kg (without driver) scaled down to 1/32 that would be 40kg. Ok maybe not true scale weight, but still, the

Carrera M6 tips the scales at 113 gr of which 42gr is made up by the body!!!!!

So this is where the first focus on this build will be..to become competitive with its 1/32nd DiSCA GT3 competition peers..the M6 will have to follow

a very strict diet.

note: another racer on another forum kindly attended me to the fact that I had used the wrong formula to calculate the "scale weight"

"Weight will scale with volume so the correct divisor is 323 = 32,768 so the "scale" weight should be 0.04 kg or 40gr"

to be continued

|

|

|

|

Grunz

Posts: 32

Registered: 3-7-2014

Member Is Offline

|

|

posted on 23-8-2018 at 20:43

|

|

|

Hi Tamar

My first (active) post here. Looking forward to this build.

I vaguely remember that discussion about not racing a carrera car against more competitive brands. Was I saying that?

About the 1:1 scale car: I thought that BMW are using the M8 for GTLM.

g

with kind regards

Gio

|

|

|

|

tamar

Posts: 804

Registered: 5-1-1989

Location: Gouda

Member Is Offline

Mood: A new beginning

|

|

posted on 23-8-2018 at 23:24

|

|

|

Hello Gio

Although you have my greatest respect...it wasn't you

Yes the car BMW now uses in GTE is the M8, its predecessor was the M6 GT-LM.

|

|

|

|

Tamar

Posts: 804

Registered: 5-1-1989

Location: Gouda

Member Is Offline

Mood: A new beginning

|

|

posted on 4-9-2018 at 13:05

|

|

|

BMW M6 GT3 / GT-LM, Step 1, de-assembling the body

So I picked up a brand new analoge Stars&stripes RLL M6 GTLM for €30. Which is about the same money you'd have to part with when acquiring a

Scaleauto or Slot.it white bodykit. Undo the 4 Philips screws to separate the body from the chassis and you can start carefully cut away the excess

melted plastic that keeps all the detail parts attached to the Body.

The first step will be to remove the tray interior, there are 6 mounting tabs which are easily identifiable. My preferred method to remove the excess

molten plastic is by using a rounded X-acto knife. These are sharp enough to cut plastic and strong enough to pry parts loose.

With the interior removed you can now acces the 4 retaining tabs that keep the one piece front and rear window section firmly stuck to the roof. Here

you'll have trouble removing the plastic with a knife (and using one might also risk scratching the windows) so this is the first opportunity to use

your Dremel. Carefully mill the excess plastic away until your flush with the clear center section.

The same can be done with the retaining tabs in the B-pilars for the side windows. Use a Philips screw driver to pop these tabs out of the

B-pillar..with care. You don't want to break them. Once free from the B-pillar you can fold the side windows forward and "un hinge" them from the

body.

Next step would be to detach the rear bumper from the body, Knife works best here, remove as little material as needed to pry the bumper off. After

all weight reductions have been done you want to be able to "melt" the bumper securely to the body again. With the Bumper off, acces to the

taillight lenses is a lot better. There too, take care to remove the minimum of "melted" material. Start on the outer tabs of the lenses first. If

you can pop these out, the lens "un hinges" itself from the inner tabs.

The one piece

headlight/Foglight cluster is the last big piece to dismount. Removing the melted material is a bit tricky here as the two tabs for each headlight

cluster are very close to the clusters themselves. Again the rounded x-acto blade is your best tool here as any slip-up with the Dremel will damage

the clusters. The one piece

headlight/Foglight cluster is the last big piece to dismount. Removing the melted material is a bit tricky here as the two tabs for each headlight

cluster are very close to the clusters themselves. Again the rounded x-acto blade is your best tool here as any slip-up with the Dremel will damage

the clusters.

To dismount the part from the body carefully slide your X-acto blade between the foglight clusters and the body splitter. The fog lights need to be

pushed inward for them to "pop" out of their surroundings. Once they are free you can carefully "wiggle" the whole piece down.

So there you have it all parts removed and a Bare Body of 20,9 gr to start with and a lot of detail bits and pieces. Last tip in this post is one from

Sweden. When ever I start a new project I use one of Ikea's "Glis" boxes to store and keep track of all the bits and pieces. At less than €4 one

of the best "Tools" for slot racing.

|

|

|

|

Grunz

Posts: 32

Registered: 3-7-2014

Member Is Offline

|

|

posted on 4-9-2018 at 19:59

|

|

|

Actually, 20.9 gr as a starting point for the body only is not that bad. I can't believe that 10 gr come from the windows, wing, and front grill

details.

What ideas do you have for the interiors? I have ordered a lexan interior for the DTM M3 and will see if it fits in the M6.

with kind regards

Gio

|

|

|

|

tamar

Posts: 804

Registered: 5-1-1989

Location: Gouda

Member Is Offline

Mood: A new beginning

|

|

posted on 4-9-2018 at 23:47

|

|

|

Hello Gio

True, 20.9 for the bare body isn't that bad for such a big car, but it still needs to loose almost half its weight. Windows are very thick and heavy,

Rear wing almost 2 gr. Small details bits like mirrors etc account for just 1,3 gram.

PRS has a vacformed M6 interior , hard to order parts from their site but I've tried. Pulled a Slot-Tec DTM M3 interior out of my Carrera M3 DTM and

it fits.

That's the easiest and biggest step down in weight you'll make on the whole car..going from 12,5 gr for the Stock interior to 1,5gr for the

Vacformed (with the DTM roll cage included)

|

|

|

|

Grunz

Posts: 32

Registered: 3-7-2014

Member Is Offline

|

|

posted on 5-9-2018 at 05:47

|

|

|

I have ordered a 3d rear wing from pro-speed. That should help in reducing some weight and have a durable wing.

Good to know about the M3 interior. I hope that the one from Slot.it is also big enough.

So we need to drop 10 gr from this body, eh? That is a lot of work. I remember spending hours with the bentley to shave off plastic.

Anyway, good to have our discussions going on again ;-)

with kind regards

Gio

|

|

|

|

tamar

Posts: 804

Registered: 5-1-1989

Location: Gouda

Member Is Offline

Mood: A new beginning

|

|

posted on 5-9-2018 at 09:55

|

|

|

Hello Gio, you'll be pleasantly surprised to see that the ProSpeed rear wing tips the scales at 0,8 gr. Maybe even less as the wing Stefan has in his

shop right now is already the Mark II version (with the correct scale slots in the supports) as opposed to the Mark I that was a straight copy of the

original (solid) Carrera wing supports.

And I know that you can't wait to order stuff...but I would advise you to have a little bit more patience.

There will be some more modifications made to the M6 chassis, these are still Beta versions. A def version will be uploaded for DISCA GT3 homologation

by end of this month.

Small differences between the beta test chassis

Last but not least...yes getting the M6 body down to a competitive weight will require copious amounts of elbow grease. But spread it over several

days..and it ain't half as bad.

|

|

|

|

Grunz

Posts: 32

Registered: 3-7-2014

Member Is Offline

|

|

posted on 5-9-2018 at 19:57

|

|

|

Too bad Tamar: I have already put in the order (it is a multi-buyer order with other members of my analog club). I am ordering the nsr version without

the front splitter and the slot.it version as well.

Please tell Stefan that if these chassis are not the final versions, it would be better to put them in the "not for sale" category.

with kind regards

Gio

|

|

|

|

Grunz

Posts: 32

Registered: 3-7-2014

Member Is Offline

|

|

posted on 5-9-2018 at 21:34

|

|

|

Update: Stefan has put the M6 chassis in the "not for sale" category now...I do not know if they are going to print it or not now.

with kind regards

Gio

|

|

|

|

tamar

Posts: 804

Registered: 5-1-1989

Location: Gouda

Member Is Offline

Mood: A new beginning

|

|

posted on 8-9-2018 at 13:54

|

|

|

Hello Gio

Yes I noticed that the chassis is "temporarily" not for sale.

When I build the Mark I version there was a slight misalignment issue with the NSR suspension screw holes. But when he printed the chassis on his own

PLA printer and checked it on the chassis Jig Stefan had build for himself it all fitted. So Stefan wanted to have the Mark II SLS printed and checked

at his workshop first before releasing it back for sale.

|

|

|

|

tamar

Posts: 804

Registered: 5-1-1989

Location: Gouda

Member Is Offline

Mood: A new beginning

|

|

posted on 10-9-2018 at 01:53

|

|

|

BMW M6 GT3 /

GT-LM, Step 2, reducing body weight BMW M6 GT3 /

GT-LM, Step 2, reducing body weight

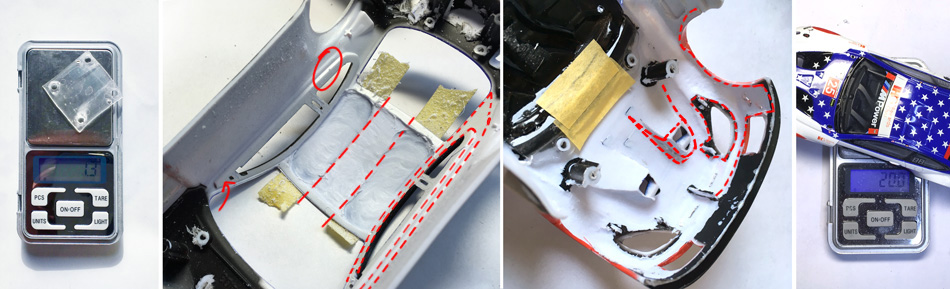

Hello Guys. Here's an update on how I put my Carrera M6 on a Diet. As with all weight loss

programs...if you need to loose some fat, its a case of shedding tiny bits of weight when ever you can, where ever you can...although in some areas it

was more like performing an outright liposuction. My preferred tools in such matters...the rounded #22 X-acto blade and these Dremel bits. The thing

you want to avoid here is...heat.

The way to do so is to keep the revs low and your finger on the trigger, meaning place one of your fingers on

the "other side" of the surface you're working on. If it gets too hot for your finger it will certainly be too hot for the plastic.

Working Top Down

Although the benefits of reducing the total weight of the body will be obvious, lowering the centre of gravity is more important than lowering the

overall weight. Which is why I like to take things step by step, and as a rule start working from the top down. So on the bottom left you see the

first and also the last big chunk you''ll be able to remove in one go" the weigth of the centre glass section.

Next area to address are the roof, the window-frames and the B & C-pillars which in true Carrera style can about 2mm thick in some places. Good

practice is always to follow the shape of the exterior as close as possible. Which is why I placed two pieces of masking tape on the roof as a guide

line for the "high" areas. I've highlighted the areas where I removed most of the material on the pictures. As a rule of thumb, if you can reduce

the wall thickness by 50% you should be able to reduce the weight by the same percentage...but practice does not follow theory by 100%.

In some areas you need more material to maintain structural integrity...more so because this car will be raced digital.

On the right you see that after doing the roof and hood the M6 tipped the scale @ 20gr. Doesn't seem like much, but this picture was taken with the

windows and the vacformed (BMW M3 DTM) interior. So the actual weight reduction on the bare body was more like 4gr.

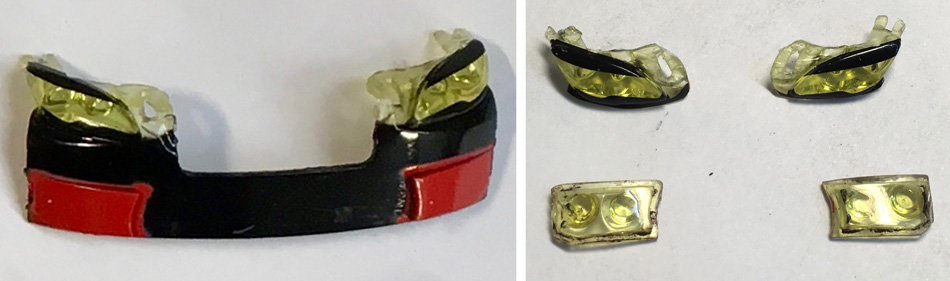

Next up was trimming the one piece head/foglight cluster. There have been cars where Carrera used the center section for the front grille. Luckily for

the M6 this is not the case so the whole section went in the bin. Trimmed the light clusters as close as possible (test fit- remove material- test fit

again) and dumped the foglights into 90% isopropyl alcohol. Too bad the guys in the factory had managed to nudge the left foglight with their

soldering iron as they hot melted the dive plates.

Not for the faint hearted

I did one more thing to reduce the weight of the clear parts, but this one is not for the faint hearted and should only be done if you're confident

that you'll be able to succeed.!!

On the M6 its not only the body that is extremely thick, the windows are as well. After cutting away the center section there's no material left to

trim, so there's but one way to reduce their weight and that is to sand them down and make them thinner. The stock side windows weight 1,2 gr, the

rear window 1,2gr, the front windscreen 1,9gr . So by applying the 50% rule there's a potential 2,1 gr to be gained here..well worth the effort.

To do so you'd best stick a fresh and sharp blade in your x-acto holder. Tape up the outside of the windows and carefully start scraping material

away from the inside. For the narrow side windows its best to do this with horizontal strokes. For the more square rear window cross hatching will

give the best results. The trick here is to avoid deep scratches, so after several passes, clean up the surface with some 1200 grit wet&dry. Repeat

the process until the scale tells you you're at 55- 60% of the stock weight. Then start cleaning up the surface with 1200/2000 and finally 4000grit.

If your personal stock doesn't go beyond 1200..sneak in to the missus bedroom and snag her nail polishing stick...if it can polish her nails...it

will also polish your windows back to a near crystal clear shine. A last buffing with Johnson wax or Tamiya polishing compound will restore your

windows to stock transparency.

After trimming all clear and body parts there are no big lumps left to remove, so instead of whole grams, you'll have to look for area's where

you can shave a few tenths off. Find five of those and you do have a gram less. Its as simple as that. You provide the elbow grease and sweat, she'll

loose the pounds (or grams in 1/32). It took me 4 nights of dremmeling, scraping, sanding and polishing to get the bare body down to 12,4 gr. Not the

50% I'd hoped for, but good enough for her to take a bath in the 90% isopropyl alcohol. After two hours soaking and half an hour with a toothbrush I

now had a 11,9 gr heavy Carrera white kit.

to be continued

|

|

|

|

Grunz

Posts: 32

Registered: 3-7-2014

Member Is Offline

|

|

posted on 10-9-2018 at 05:48

|

|

|

Excellent Tamar. 11.9 including the all the windows and small parts?

I was wondering if you were going for the stock Carrera Stars&Stripes livery.

Now the questions is which livery you are going for! ;-)

Ah, on another note: would be possible for you to make a step-by-step tutorial on how to make your own decals (from design to print) using your fav

editing software? I know that you have done one for the NSR corvette, but that was covering mainly your technique to convert the body from 3D to 2D.

Maybe not for this car, but as an idea for a future tutorial.

with kind regards

Gio

|

|

|

|

tamar

Posts: 804

Registered: 5-1-1989

Location: Gouda

Member Is Offline

Mood: A new beginning

|

|

posted on 10-9-2018 at 20:29

|

|

|

Hello Gio

No, not at this stage, the 11,9 gr as you can see in the picture, was for the bare body only. Windows, wing and detail parts will add another 6,8

gram.

As for the livery, I'm still in doubt, but black is beautiful

As for the decal tutorial, the NSr C6 Corvette topic on Slotforum did cover the steps on how to make decals but I'll think about it.

|

|

|

|

tamar

Posts: 804

Registered: 5-1-1989

Location: Gouda

Member Is Offline

Mood: A new beginning

|

|

posted on 15-9-2018 at 12:22

|

|

|

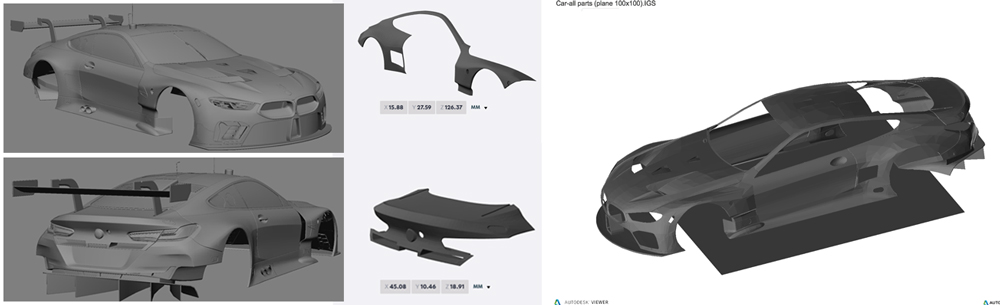

2 x 6 = 8

I guess that by now most of you will have done the math and concluded that the answer to the "teaser" in the title isn't "12" With Team Mission8

just having made its entry for the 2019 DiSCA Oxygen Le Mans 24hrs it is time to reveal the ultimate goal for this W.I.P to build the two BMW M6

cars... and that is to build and race BMW's latest ultimate GT.... the M8 GTE.

Its a big project (and I'm not just referring to the M8's size) to big for just one person to complete. Design work on the 3D model is already at

an advanced stage with the first Master print due by late November. 3DP Chassis design and development already in full swing in cooperation with

ProSpeed. Decals and hopefully milled aluminium 5 spoke BBS wheels by Slotfabrik. Full light set by Z-machine etc etc.

First debut planned @ the Suzuka WEC race in Best, NL on Jan 27th 2019.

|

|

|

|

tamar

Posts: 804

Registered: 5-1-1989

Location: Gouda

Member Is Offline

Mood: A new beginning

|

|

posted on 2-8-2019 at 19:31

|

|

|

A long overdue update

Hello Heath (and all other readers)

I'll most likely split these post into a separate M6 and M8 topic later on, I've been trying to catch up on my back log of build post on LMS over

the Holliday season.

Made good progress so far, but each update has also spurred some new questions posted which required replies etc etc.

Got a lot of pictures ready for updates on the M6 and the M8 but with the clock ticking ever louder for the Suzuka 6hrs time has become a valuable

commodity.

But I can fully understand you asking for updates after 4 months of sheer radio silence on the M6 and M8 projects...so here's a small preview of the

upcoming episodes.

(note: the following preview contains spoilers and some pictures may be considered disturbing for modelers)

Episode 3: From Dark Horse to Darkest hour

How the M6 GT3 became a dark horse for its first race in Mechelen ( B ) with some 3DP chassis tuning.

So dark in fact that besides smashing the pre race lap record....concerns over visibility on the dark Carrera track...

...lead to a last minute swap to a lighter livery. A decision that resulted in one of my darkest hours in slot racing.

Episode 4: Plan B for Belgium

When the going gets tough..the tough get going. How Marc Wiggers (Wiggie) testbody became plan B for Belgium in less than 24hrs.

Back to black , bold and not so beautiful but with some new and fitting decals, the M6 GT3 scored 4th place on its race debut in the analog 10hrs of

the DCSA in Mechelen Belgium.

Episode 5: 3B modelling

How Babylon still rules when it comes to translating 3D models into 3D prints and Slotcars. Trails and tribulations of working with different 3D

software platforms

This episode is most likely to create its own spinn-off series in 2019 as "mission8"

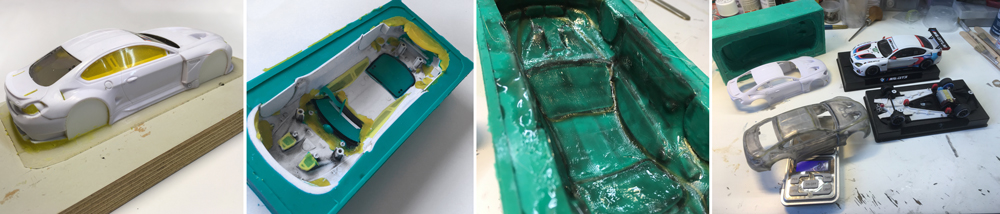

Episode 6: Lament for a Lightweight body

With the M8 3d model running a bit late it was back to square 1 for the M6. But whatever I tried the Carrera body would always be a bit too heavy in

DiSCA GTLM trim.

So time to create a M6 master, a silicone mould and do some lightweight lamination.

So there you have it, a preview of future 2x M6= ? topic posts to be made (although by now that title should be changed to 3x M6)

But as I mentioned before, most likely these episodes will be not aired before February

I hope you guys can understand and have a bit more patience.

|

|

|

|

tamar

Posts: 804

Registered: 5-1-1989

Location: Gouda

Member Is Offline

Mood: A new beginning

|

|

posted on 2-8-2019 at 19:43

|

|

|

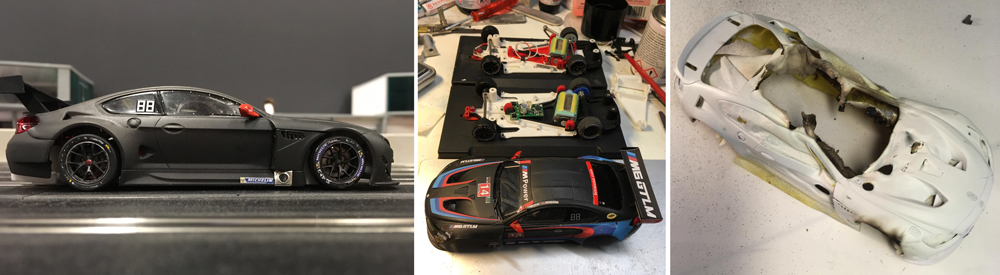

Two days after the race before

Last weekend a final stage of the 2x6 project was completed, a DiSCA spec, GRP laminated, 3DP chassied BMW M6 GTLM started in the 2019 Low

Lands Suzuka 6hrs. All the months of designing, developing, building and testing, were rewarded with flawless race.

The M6 GTLM taking the checkered flag as 1st in class, 2nd overall with but a few optical scratches.

But most important, all the lessons learned on set-up and preparation with the M6 can be used for future projects...like the M8.

As they say, there's no better way to verify your testing than race conditions.

My post in the Event Forum on the 2019

Suzuka Double digital spurred GregK to post the following question:

I have moved my reply to this topic as it is more "on topic" here than in the event thread, and have added a few more pictures of the

"finished" car

Hello Greg

The short and honest answer would be: Don't want to know...and really don't want to know.

But that answer would be disrespectful of an honest question posed out of interest .

The problem is, to give you a complete answer your question is too brief.

I assume your inquiry is about the car below, the GRP version of the Carrera BMW M6 GTLM ?

So what would I need to include to the time and cost involved in getting this car on the grid?

BMW M6 GTLM Breakdown

If I had to make an exact copy, like a T-car, the cost would be:

3DP parts, chassis, pod & wing €45

GRP laminated body €3 material costs

Slotfabrik Decal set €20

VAC formed PRS interior €7

Windows (cut from blister wrap) €0

4x Inserts € 5

Cast resin detail parts €3 material costs

Running Gear (motor, gears, titanium rear axle, 2x ballbearings, NSR wheels, carbon front axle, Delrin fronts) €55

Oxigen O201B2 chip €35

Z-machine Light kit €27

All in all about €200, give or take a few quid.

To build the T- car would require:

Body lamination & clean up 3 hrs

Prepping front and rear rims & tires 2hrs

Chassis assembly & set-up running gear 6 hrs

Body & detail paint: 4hrs (30 min airbrushing, rest is cleaning, masking etc etc)

Installing Z machine light kit and lights 3 hrs

Windows 0,5 hrs

Decalling 2 - 3 hrs (although the boys did this one in 45min to make Tech and Qualification  ) )

I probably forgot some things and have used optimistic times...but all in all about 24hrs.

But...that would be if I had a car to copy the whole set-up from, something I could duplicate.

The team started the M6 project in September

last year, this is the 3rd M6 we've build since.

During development design and testing we used 3 Carrera cars, 5 3DP chassis, 6 motor pods, 8 rear wings, 4 motors, 3 O2 chips 20 sets of tires, 1kg

Silicone for Moulds etc etc etc. Countless hours on Skype with Stefan Nalbach (Prospeed) to discuss the next chassis version, some 20 hrs drawing and

test fitting the decalsheet.

Beside the time spend developing & building we spend several weeks testing, testing and testing at the track....and still the car was only finished 20

minutes before the end of Qualification.

(note: If I look at the images, she's still not finished, missing detail bits and decals, some black paint here and there.....there never seems

to be enough time to finish it all in time for tech...

but at least she was legally blonde)

Should I add these cost and time to that of the single BMW M6 GTLM we raced @ Suzuka to calculate the total time and cost?

Don't want to know...and really don't want to know.

But...it did run flawlessly from start to finish, took class pole (2nd time overall) won its class...and would have finished 2nd overall, if not for

my botched up driving, but 3rd overall was a very good result.

So it was all worth the money and effort.

(note: I only build and race DiSCA spec cars, maybe 2-4 cars per year. They're all for team races so cost and time are shared over more people

(sort off  ) )

|

|

|

|

|