| Pages: 1 2 |

marco

Posts: 64

Registered: 3-1-2007

Member Is Offline

Mood: Doesn't have to last forever to be great!

|

|

posted on 25-5-2008 at 02:33

|

|

|

PLAFIT SLP -- Q&A ???

| Quote: | I

was about to suggest the same. I have used the Schöler option a few times too. FYI the holder comes in two sizes LONG and SHORT. I see you have the

long version and that is why you have the Spur gear the wrong way around. and the problem that the gear , if any bigger , will foul on the bottom

Plate.

The short version moves the motor out further and eliminates the problem. Cool thing about it is that you can choose the motor height your self.... IO

now use the "Felgendreher " part but it is not adaptable and costs 3 x the Schöler. Your Rear clamp is way cool! Well done! I now have a part

that is similar to a motor holder, works well but is way too expensive. Fola |

PLAFIT SLP -- Questions & Answers ?

There are quite a number of us here in the USA and CANADA that have finally managed to 'scarf up' the SLP chassis and all of the various bits and

pieces . . . well at least the ones that we know about . . . in preparation for the upcoming IMCA WORLDS. Well . . . preparation may be a bit of a

generous word . . . actually a lot of bits and pieces in a bag . . . and what the hell are we goning to do now?

Fred Hood just got his stuff . . . and there are enough emails going back and forth that we will probably be related in a couple of weeks . . . and

that is not a pretty thought on either side of the family. So I thought we could use this thread to ask some of the SLP pros some very obvious and

moronic questions . . . but hey guys . . . we are doing are best to catch up. Have mercy!

Question 1 -- The 3 degree independent fronts.

Most of us are using the Scaleauto RTR front wheels that are 25.5mm dia. It is our understanding that the front tires remain the same . . . or ground

flat . . . so that with the 3 degree independent mountings, only the inside edge of the tire has contact with the track. Seems obvious . . . but is

this the format?

Mark Campbell

Scale Racing America

.

|

|

|

|

Big Al

Posts: 221

Registered: 4-6-2004

Member Is Offline

Mood: No Mood

|

|

posted on 25-5-2008 at 07:55

|

|

|

Hi Mark,

The way I understand it, you are required to have the entire width of the front tire flat on thew tech surface, even with the Cambered fronts. (But,

read on..)

This means the Scaleauto Fronts are too small, and you'd need to mount a larger profile Rubber or Sponge Front, and then true AT AN ANGLE, so that

the front wheels present a flat surface when on the tech block. (However, it DOESN'T say this specifically, for the 430 Cars..)

Technically, this is a VERY challenging setup to do, because the outside of the wheel will naturally be higher than the inside of the wheel, and can

also interfere with your clearance between the body and the wheel, or you end up with the front of the car sitting a little higher than you'd

like.

If IMCA Tech does it's job preprly, and I agree, this might need to be clarified first, because if I read the rules correctly, the MIN Diameter of

the fronts must be 25.5mm, and that would have to be measured on the inside of the wheels, with the Min width being 5mm, so the outside of the wheels

have to be larger than the inside 25.5 mm..

So, to simply add a subtle wider track on the front of the car means the height of the body over the wheels will be negated, and could be a

problem.

The other, safer option all round, would be to use the standard straight Ind Fronts, so the wheels won't need to be trued at an angle, and your

clearance between the wheel and the body will be better, but your width will be smaller.. It's a difficult decision to make.

It clearly states under the FIA GT Rules, "Standing on the tech block the front wheels must touch the block over the full 5mm", but it DOESN'T say

this for the 430 cars.. Does that mean it's ok to ONLY have the inner edges touching the track? ie: a flat wheel on a camber?? This would certainly

help all the clearance issues, but, I don't know if the handling would be too good..

What do the Pro's say??

Cheers

Big Al

|

|

|

|

marco

Posts: 64

Registered: 3-1-2007

Member Is Offline

Mood: Doesn't have to last forever to be great!

|

|

posted on 25-5-2008 at 14:35

|

|

|

Hi Al,

Grinding the tires to the match the 3 degrees of the camber was also my initial thinking . . . but as you point, where is the min tire OD measured . .

. and looking at it, I don't think the Hudy adjusts that much . . . so you freehand it? And then none of the old pros here could possibly think of

what the advantage would be over the 0 degree independents -- if the contact patch is essentially the same. As you say, the F430 rules do not

parallel the GT rules as to contact of the front wheels on the tech block. I have already sent a note off clarification several weeks ago to JPvR on

this point . . . so it must be intentional. The top guns' are in Alsdorf wrapping up the EEC this weekend . . . very jealous . . . so we will have

to wait for some comment. In the meantime I will post a second question.

Mark.

.

|

|

|

|

marco

Posts: 64

Registered: 3-1-2007

Member Is Offline

Mood: Doesn't have to last forever to be great!

|

|

posted on 25-5-2008 at 15:39

|

|

|

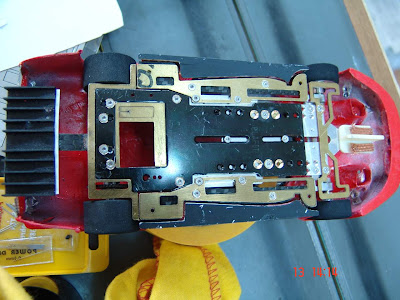

Question 2 -- Filling in the motor box hole

The baseplate for the SLP is cut with a hole to fit the BISON . . . and we run the smaller PROSLOT can. I have seen a lot of the motor holes filled

in completely . . . or in part . . . with brass plate. I assume that these various brass fill plates are being soldered in to the chassis . . . as

the only F430 rule forbidding solder is the mounting of the motor. Do we have it right?

Mark Campbell

Scale Racing America

.

|

|

|

|

Gert

Posts: 400

Registered: 31-8-2003

Location: Belgium

Member Is Offline

|

|

posted on 25-5-2008 at 16:09

|

|

|

| Quote: | Origineel gepost door marco

Question 2 -- Filling in the motor box hole

The baseplate for the SLP is cut with a hole to fit the BISON . . . and we run the smaller PROSLOT can. I have seen a lot of the motor holes filled

in completely . . . or in part . . . with brass plate. I assume that these various brass fill plates are being soldered in to the chassis . . . as

the only F430 rule forbidding solder is the mounting of the motor. Do we have it right?

Mark Campbell

Scale Racing America

. |

Hi there to you all

this is the way I sorted out the hole problem, I used a brass plate to close it up and made for the heat a hole in the middle of the plate.

It is glued in wit thin superglue and it should be the same thicknes as the chassisplate.

Picture

of my chassis

Greetz Gert who just returned from Alsdorf , and I can tell you all it was a Great event

|

|

|

|

Big Al

Posts: 221

Registered: 4-6-2004

Member Is Offline

Mood: No Mood

|

|

posted on 25-5-2008 at 17:40

|

|

|

Mark,

It's also possible to use the S24 Base Plate. This doesn't have a hole in it, and has almost identical dimenesions.

Regards

Al

|

|

|

|

marco

Posts: 64

Registered: 3-1-2007

Member Is Offline

Mood: Doesn't have to last forever to be great!

|

|

posted on 25-5-2008 at 21:07

|

|

|

| Quote: | Originally posted by Gert

Hi there to you all

this is the way I sorted out the hole problem, I used a brass plate to close it up and made for the heat a hole in the middle of the plate.

It is glued in wit thin superglue and it should be the same thicknes as the chassisplate.

Picture

of my chassis

Greetz Gert who just returned from Alsdorf , and I can tell you all it was a Great event |

Hello Gert,

How did you attach the brass plate to the chassis . . . glue or solder? If everyone is filling the hole in the chassis, there must be a need to get

more weight to the back of the SLP to get closer to the weight of the BISON motor . . . as this was the original design for the SLP chassis ?? Also

important, how did you do at the race in Alsdorf?

Mark

.

|

|

|

|

slotmad

Posts: 180

Registered: 26-6-2003

Member Is Offline

Mood: still waiting

|

|

posted on 26-5-2008 at 08:07

|

|

|

Hi Mark,

If you make a contra holder for your motor, you can use the new holder also to attach the brass plate. Drill a whole through the contra holder and the

brass plate to mount a mother and nut.

greetz

Henri

Slotmad

|

|

|

|

marco

Posts: 64

Registered: 3-1-2007

Member Is Offline

Mood: Doesn't have to last forever to be great!

|

|

posted on 29-5-2008 at 03:16

|

|

|

Starting to get some direction on the motor hole in the chassis. Still looking for some input on the 3 degree independent wheel mounts . . . and if

the wheels are also ground at 3 degrees . . . and can this be done on a Hudy . . . and ????? Could use a little help on this mystery.

Mark

.

|

|

|

|

lafficus

Posts: 16

Registered: 29-9-2007

Member Is Offline

Mood: No Mood

|

|

posted on 29-5-2008 at 07:01

|

|

|

Hi Marco.

I don't know how well you speak (or read) german, but you can find som info on the hudy/camber issue here:

http://www.slotracing-forum.de/forum/messages/113989.htm

|

|

|

|

sloefspeed

Posts: 71

Registered: 27-4-2007

Member Is Offline

Mood: No Mood

|

|

posted on 29-5-2008 at 14:47

|

|

|

| Quote: | Originally posted by marco

Starting to get some direction on the motor hole in the chassis. Still looking for some input on the 3 degree independent wheel mounts . . . and if

the wheels are also ground at 3 degrees . . . and can this be done on a Hudy . . . and ????? Could use a little help on this mystery.

Mark

. |

Hi Marc,

the complete hudy with the camber kit on it is for sale at :

http://www.slotracing-werk.de/scaleracing/rub1~Werkzeuge~artnr~11756~pn~18~func~det~wkid~1952106755314416.html

If you already own a hudy, the kit is available separately at :

http://www.slotracing-werk.de/scaleracing/artnr~11240~rub1~Werkzeuge~pn~18~func~det~wkid~1952106755314416.html

piece of cake... but with a pricetag....

see the pictures with both the articles. Of course it's not JP's favourite slotshop, but there is very little that can be done about that... Seems

not imposible to make by yourself, but I guess the price asked is worth the time you would have to put into making it yourself

Sure hope this helps,

VBR

Raymond

|

|

|

|

marco

Posts: 64

Registered: 3-1-2007

Member Is Offline

Mood: Doesn't have to last forever to be great!

|

|

posted on 29-5-2008 at 20:24

|

|

|

Hi Raymond

Thanks. I have sent my order off . . . and now all the guys here will want to grind their tires  But I am still trying to understand how it works? Hey Fola . . . you're one of the SLP top guns . . . I know

how camber works on a 1:1 car . . . but I have seen some of the chassis you guys are running and they are sprung so hard there is barely any movement

at all. Still thinking . . . But I am still trying to understand how it works? Hey Fola . . . you're one of the SLP top guns . . . I know

how camber works on a 1:1 car . . . but I have seen some of the chassis you guys are running and they are sprung so hard there is barely any movement

at all. Still thinking . . .

Mark

|

|

|

|

tamar

Posts: 804

Registered: 5-1-1989

Location: Gouda

Member Is Offline

Mood: A new beginning

|

|

posted on 29-5-2008 at 23:39

|

|

|

Just an increase trackwidth...

...that's all it does.

Come on guys, you are making way too much out of this cambered fronts stuff.

The only thing it does (compared to the non cambered independend frontaxle stubs) is that it increases your track width with 2mm.

A set of wheels with a ±25mmø and a 3˚camber will measure 80mm @ the top and 82mm at the bottom. That's it (besides that it looks good)

The downside of the independend front axle stubs is that they tend to move during a race. They tend to go to a toe out position. Not that it

infleuences the "steering" that much but the wheels can start rubbing the body work.

|

|

|

|

Whizzkid

Posts: 6

Registered: 7-11-2007

Member Is Offline

Mood: No Mood

|

|

posted on 30-5-2008 at 08:36

|

|

|

I think the biggest question here is, does the whole surface of the tyre have to touch the track as in the GT rules? If not, it leaves the door open

for some creative shaping of front wheels if using the flat independent front setup, which could also help increase the width.

|

|

|

|

tamar

Posts: 804

Registered: 5-1-1989

Location: Gouda

Member Is Offline

Mood: A new beginning

|

|

posted on 30-5-2008 at 09:37

|

|

|

| Quote: | Originally posted by Whizzkid

I think the biggest question here is, does the whole surface of the tyre have to touch the track as in the GT rules? If not, it leaves the door open

for some creative shaping of front wheels if using the flat independent front setup, which could also help increase the width. |

It also leaves the door open for "creative shaping of front wheels" if you use the normal standard front axle.

Guys....as you know my "official" duties for IMCA have ended with the conclusion of the 2008 EEC, which means that I am no longer "involved" in

any of the technical matters concerning IMCA rules.

I would suggest that you post these type of questions about IMCA rules in the "unofficial IMCA forum" on this site. All I can do is ask guys like

Bob Demeyer and Jean Marie Tillen to look at the forum once in a while and hopefully your questions will be answered and grey areas will be

"clarified"

|

|

|

|

Gert

Posts: 400

Registered: 31-8-2003

Location: Belgium

Member Is Offline

|

|

posted on 31-5-2008 at 09:04

|

|

|

| Quote: | Origineel gepost door marco

Hello Gert,

How did you attach the brass plate to the chassis . . . glue or solder? Mark

. |

Hi Mark

We used a thin superglue to set the plate in to the hole, when you would solder it you have to heat up the baseplate to high and it could bend due to

the heat.

So all the racers I know use superglue

And about Alsdorf , well the goal was that Remco my teammate could win the cituationcup, and we reached that goal , overall in the EEC we got the 8

spot I guess   , ,

but that is not importand, we had fun and fights for the possition in the race that is the part that counts for me the most

Greetz Gert.

|

|

|

|

fola

Posts: 338

Registered: 8-10-2006

Location: The PLANET Earth.

Member Is Offline

Mood: ADMIN wanna be I D A M N right I'm building again & Sleepless in the celler

|

|

posted on 1-6-2008 at 08:06

|

|

|

| Quote: |

Thanks. I have sent my order off . . . and now all the guys here will want to grind their tires  But I am still trying to understand how it works? Hey Fola . . . you're one of the SLP top guns . . . I know

how camber works on a 1:1 car . . . but I have seen some of the chassis you guys are running and they are sprung so hard there is barely any movement

at all. Still thinking . . . But I am still trying to understand how it works? Hey Fola . . . you're one of the SLP top guns . . . I know

how camber works on a 1:1 car . . . but I have seen some of the chassis you guys are running and they are sprung so hard there is barely any movement

at all. Still thinking . . .

Mark |

Mark (0),

I use the cambered fronts - just coz they look good and i am a sucker for detail and gimmicks. Perfomance is imho not really enhanced. You do get a

wider spur in the front but you also have a larger contact area with the track since the wheel must be 5 or 8mm wide... more contact = more roll

resistance...... (Who cares.... as long as it looks good ;-).

I actually run fronts that are almost 10mm wide....

All rules state how much tire must be in contact with the track....

RfH runs with no springs at all..... my brain never understóod how and why that should work at all.... now i run ALL Cars/series without springs

difference none. Just as good...and less risk of wheel fender contact.

In the SLP Free wheelers and cambers are actually not allowed...

My SLP plates also have the Gap filled up with a custom Laser cut Brass plate that fits tightly into the existing opening and is secured with super

glue and YES. It is a weight thing.

C U Soon??

Fola

|

|

|

|

JustMe

Posts:

Registered: 1-1-1970

Member Is Offline

|

|

posted on 1-6-2008 at 11:21

|

|

|

Cambers

Guys, the cambers are not mysterious at all!

It are still hardered front wheels, which roll and act in the EXACT same way as a normal stance of the wheel. Indeed, in some cars it's beneficial

cause it provides more room on the above side in the body, while still you can run you wished width at the underside of the wheel. Like on the

F430.

It looks cool and realistic.

It's a bit harder to shape and sand to give them their 3 degree angle, but at least myself always put the finishing touches to any front wheel by

hand. Here it's just the same thing. Just screw together your camber parts as a loose item, meaning only via the crossbar, the axles holder and those

'pyramid' alu blocks. Then during sanding the wheels, just fit them on the camberpart, and you'll see where you're going. It's really not that

hard, and coming from me, who only made maybe 6,7 or 8 sets of front wheels in my slotracing career. Never any rear wheels

And they still have the same roll resistance, cause the 0 degree front wheels also have to touch the track by 5mm width, same as on the cambers.

|

|

|

|

marco

Posts: 64

Registered: 3-1-2007

Member Is Offline

Mood: Doesn't have to last forever to be great!

|

|

posted on 2-6-2008 at 17:27

|

|

|

| Quote: | Originally posted by JustMe

Guys, the cambers are not mysterious at all!  It are still hardered

front wheels, which roll and act in the EXACT same way as a normal stance of the wheel. Indeed, in some cars it's beneficial cause it provides more

room on the above side in the body, while still you can run you wished width at the underside of the wheel. Like on the F430. It are still hardered

front wheels, which roll and act in the EXACT same way as a normal stance of the wheel. Indeed, in some cars it's beneficial cause it provides more

room on the above side in the body, while still you can run you wished width at the underside of the wheel. Like on the F430. |

Thanks Guys,

That pretty much answers it . . . but one last detail . . . and this may vary from series to series . . . but typically where is the minimum tire OD

measured when the wheels are ground to 3 degrees to match the camber? Thanks for the insight.

Mark

.

|

|

|

|

JustMe

Posts:

Registered: 1-1-1970

Member Is Offline

|

|

posted on 2-6-2008 at 17:40

|

|

|

measuring

Hey Mark,

Pure technically speaking, the wheels should be the prescribed diameter on all areas of the wheel, BUT ( do I love those BUT's  ) generally it means that the biggest diameter measured counts, and especailly

on cambers that means the outer side of the wheel. ) generally it means that the biggest diameter measured counts, and especailly

on cambers that means the outer side of the wheel.

|

|

|

|

Checa

Posts: 27

Registered: 7-2-2008

Member Is Offline

Mood: No Mood

|

|

posted on 2-6-2008 at 22:38

|

|

|

All this should be in the rulebook.

Where is measured the diameter of the front wheels?

Where is measured the total width of the front axle? above (minimum) or down (maximum)?

You can run with asymmetric wheels?

I think all this and the issue of a single chassis manufacturer must solve, not allowing the camber of 3 degrees

|

|

|

|

Big Al

Posts: 221

Registered: 4-6-2004

Member Is Offline

Mood: No Mood

|

|

posted on 3-6-2008 at 11:12

|

|

|

I read that differently Nick. And I see the Rulebook was mysteriously "fixed" to read 5 mm touching the track surface for the F430's.

The Rulebook says the MIN OD must be 25.5mm, so on cambered fronts, that HAS to be the inside of the front wheel, therefor the outside would naturally

be a larger diameter. There's no way the outside of the fronts can be 25.5mm OD on 3' Cambered fronts, and the car passes Tech! Then the inside

diameter would be less than 25.5mm..

Big Al

|

|

|

|

slotmad

Posts: 180

Registered: 26-6-2003

Member Is Offline

Mood: still waiting

|

|

posted on 3-6-2008 at 12:27

|

|

|

Hi Guys,

As long as I race the width of the front wheels is measured at the largest point (the outside). More interesting to me is how the front spur will be

measured at the cambered wheels? At the widest point, the point where the wheel touches the tech plate or in the middle of the wheel?

Slotmad

|

|

|

|

Whizzkid

Posts: 6

Registered: 7-11-2007

Member Is Offline

Mood: No Mood

|

|

posted on 3-6-2008 at 14:32

|

|

|

| Quote: | Originally posted by Big Al

The Rulebook says the MIN OD must be 25.5mm, so on cambered fronts, that HAS to be the inside of the front wheel, therefor the outside would naturally

be a larger diameter. There's no way the outside of the fronts can be 25.5mm OD on 3' Cambered fronts, and the car passes Tech! Then the inside

diameter would be less than 25.5mm..

Big Al |

I have to agree with Al on this one!!!

|

|

|

|

marco

Posts: 64

Registered: 3-1-2007

Member Is Offline

Mood: Doesn't have to last forever to be great!

|

|

posted on 3-6-2008 at 17:20

|

|

|

| Quote: | Originally posted by slotmad

Hi Guys,

As long as I race the width of the front wheels is measured at the largest point (the outside). More interesting to me is how the front spur

will be measured at the cambered wheels? At the widest point, the point where the wheel touches the tech plate or in the middle of the wheel?

|

Good catch on the front spur width with the cambered fronts. It's getting better! I have added this question to the others for Jean Marie as posted

on the UNOFFICIAL IMCA FORUM for clarification. Thanks.

Mark

.

|

|

|

|

| Pages: 1 2 |