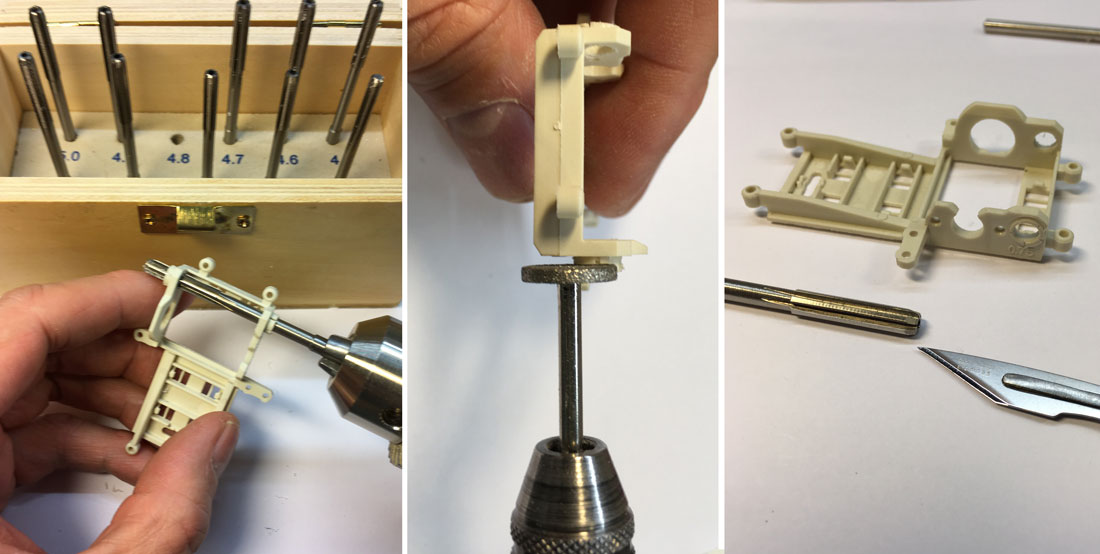

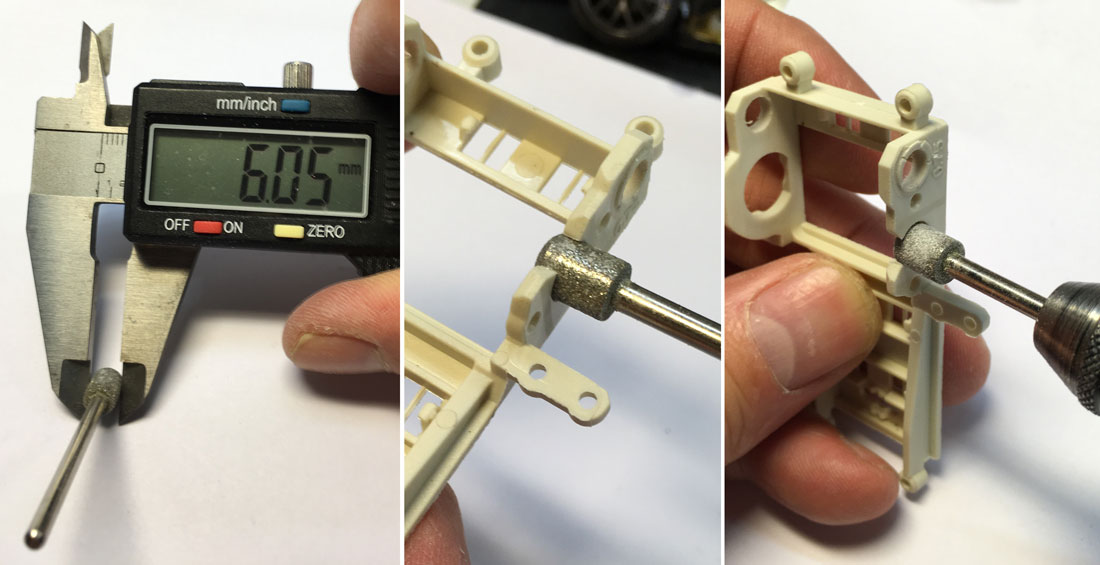

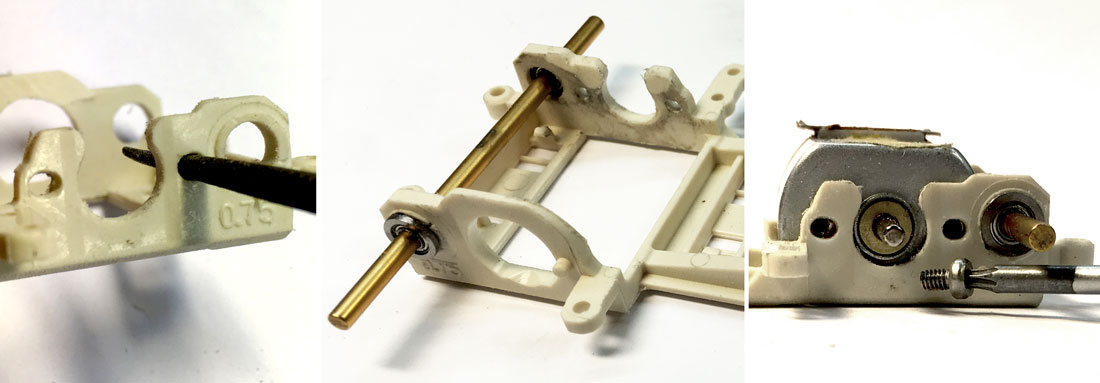

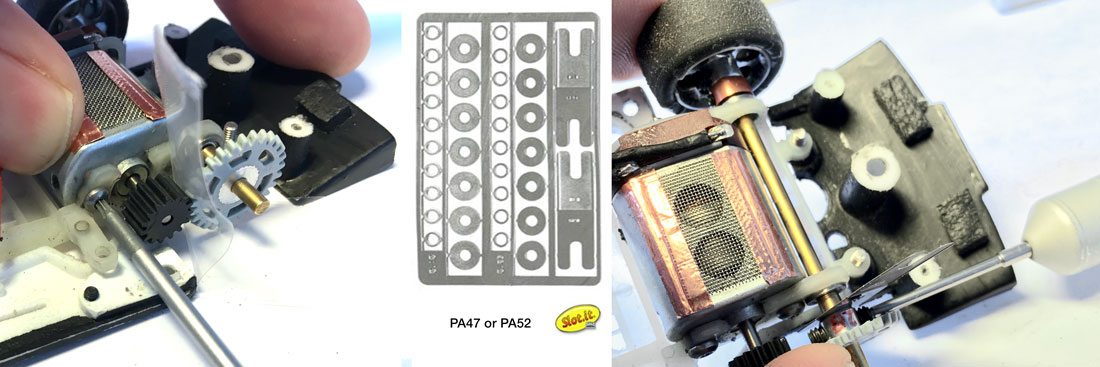

Remove axle play tool.

So there you have it, an idiot proof procedure to set the same and correct amount of axle play and have a perfect gear mesh, any time, every time.

As usual the most simple ideas can be the most ingenious ones, and by adding the axle play tool to the PE spacer set a Slot.it PA47 and/or PA52 is

really one of the best buys you can make.

tamar - 7-3-2019 at 09:15

The Road to Le Mans 1/32: 4 weeks and

counting

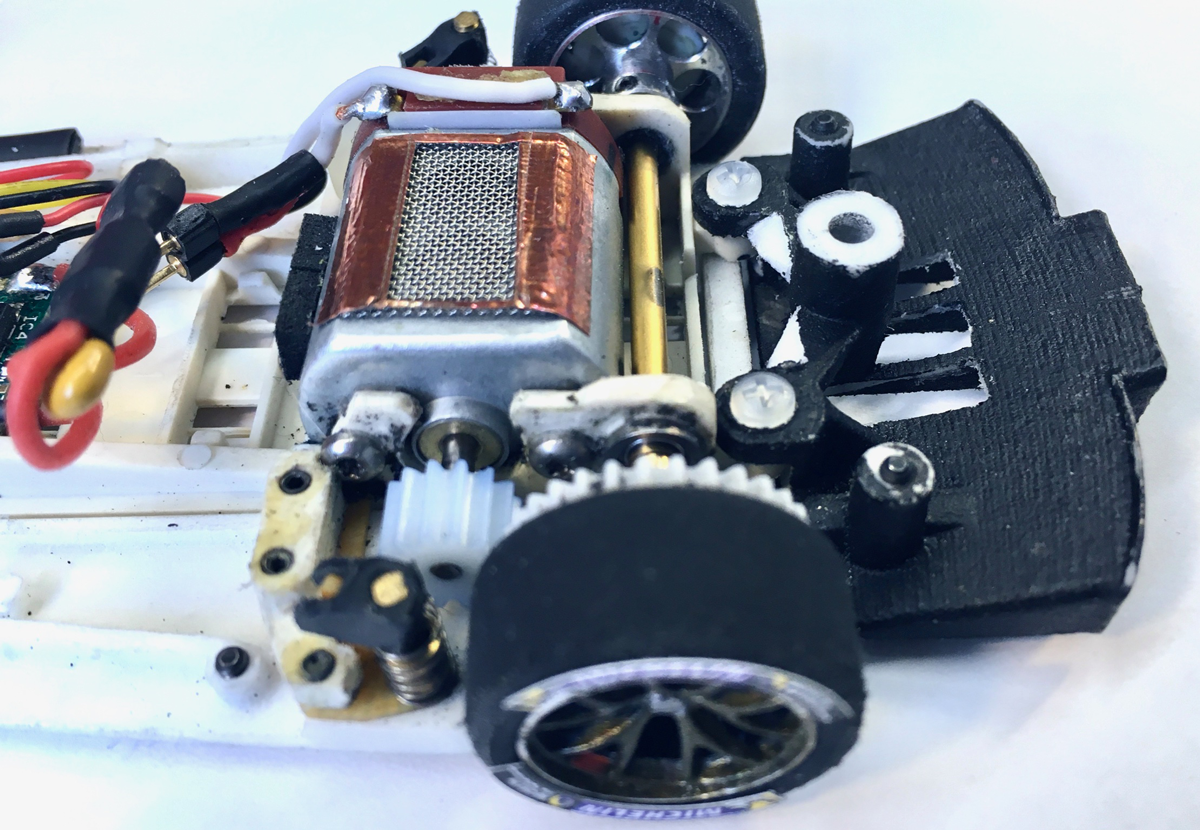

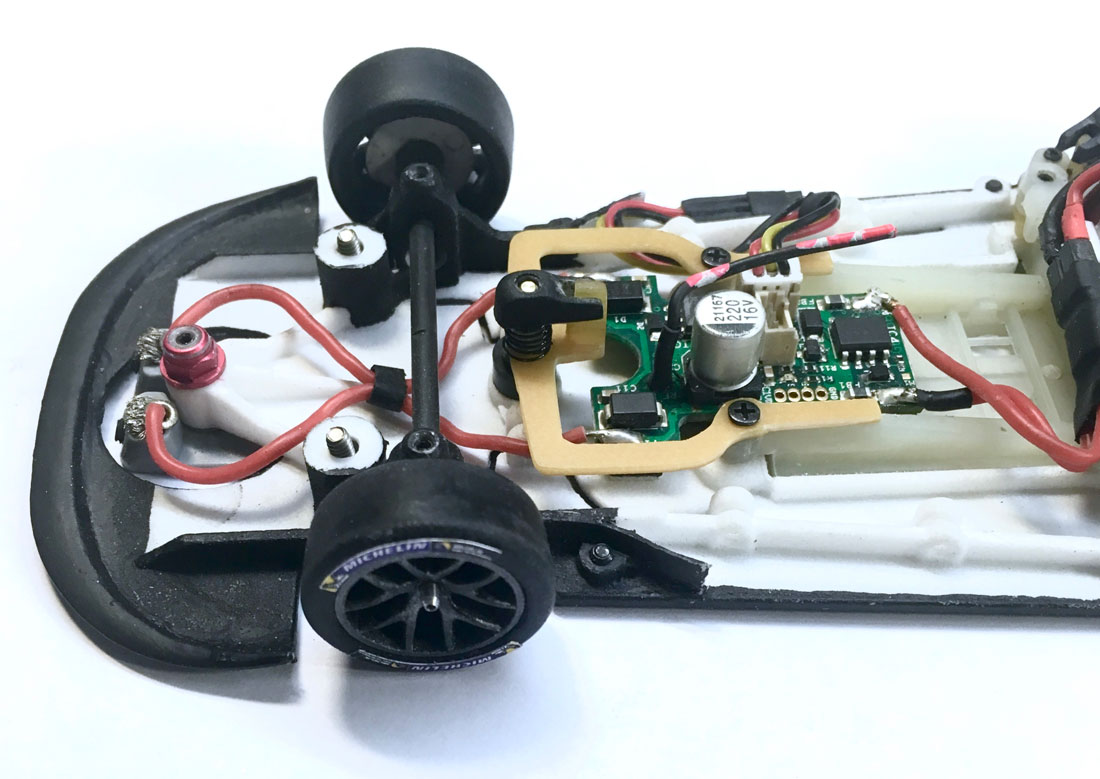

Just 30 days before the start of the first practice session in Henley in Arden. With the MK2 Sidewinder chassis now on the bench, work in the last

week was focussed on prepping the MK2 chassis and converting the MK1 chassis to a AW configuration. We've got a test session planned this Saturday

where the goal is to give both chassis a thorough endurance test and compare both configurations.

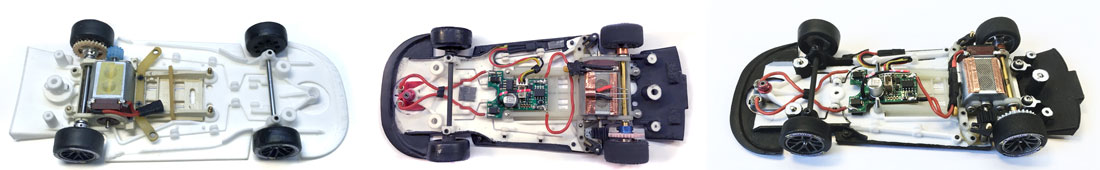

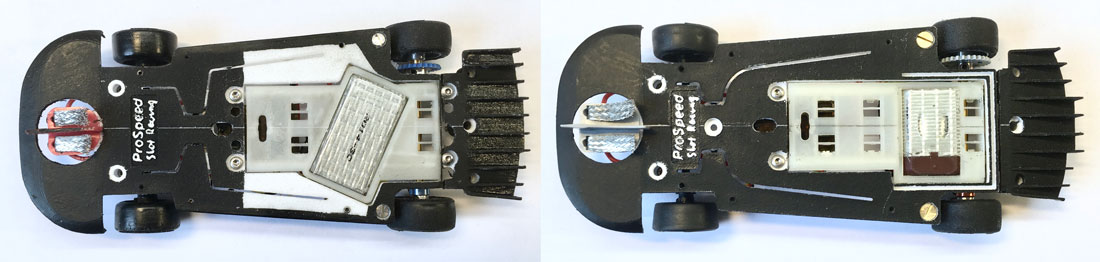

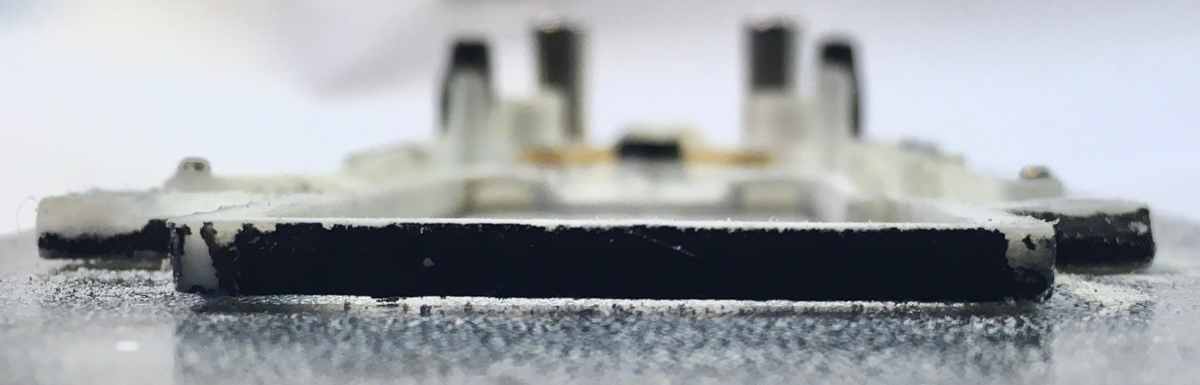

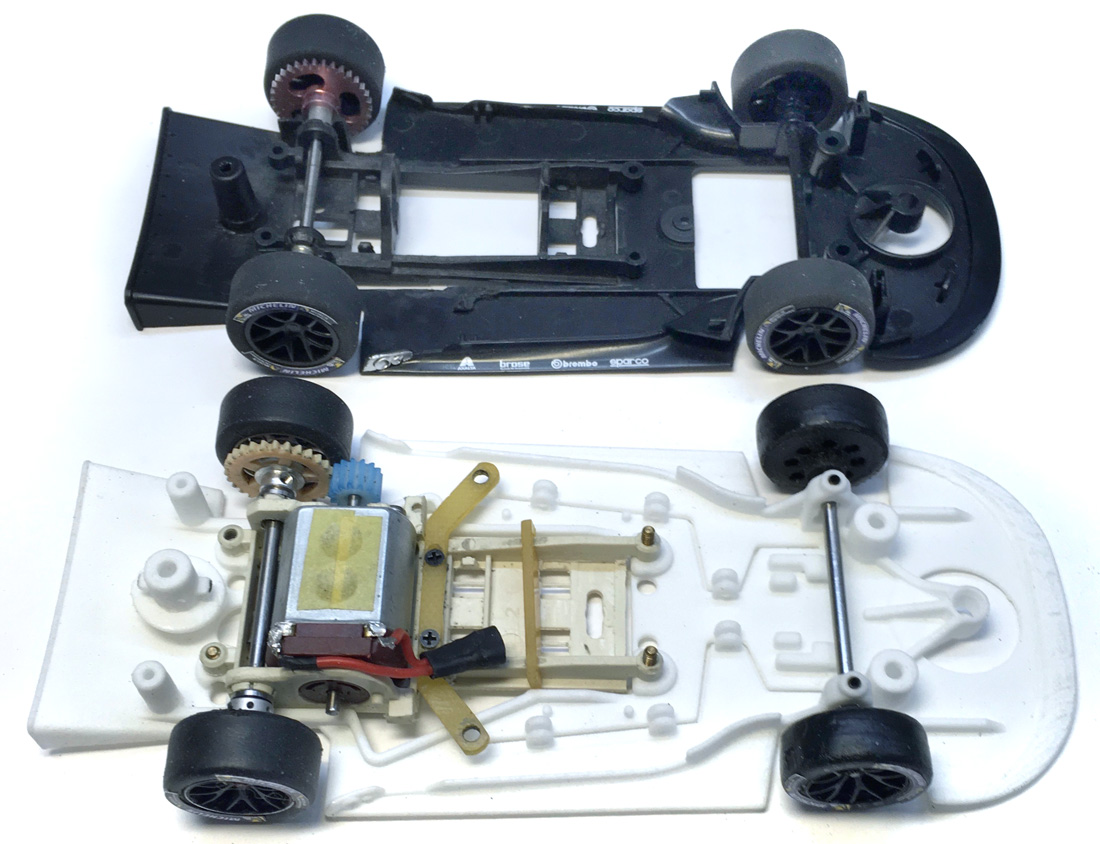

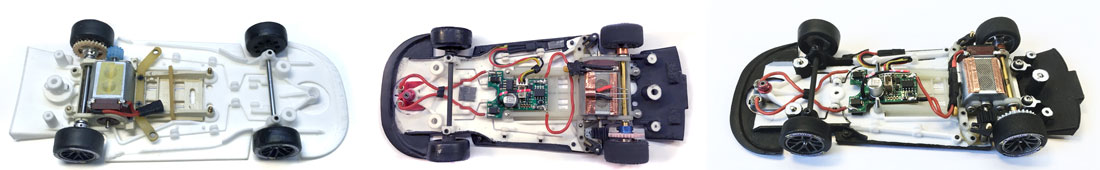

From prototype to production

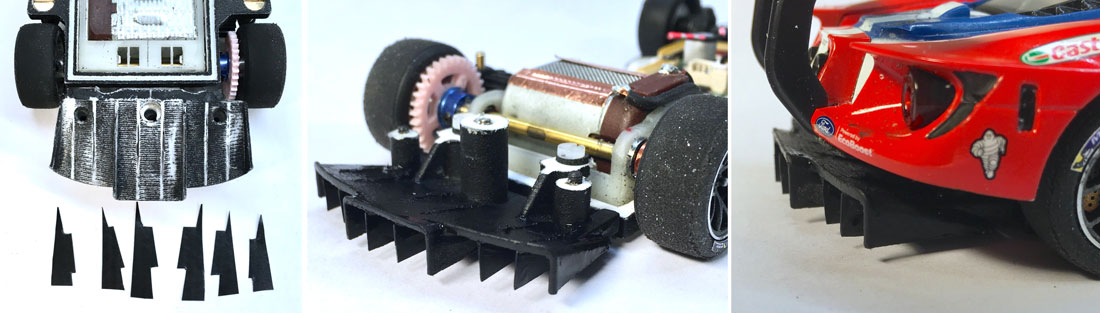

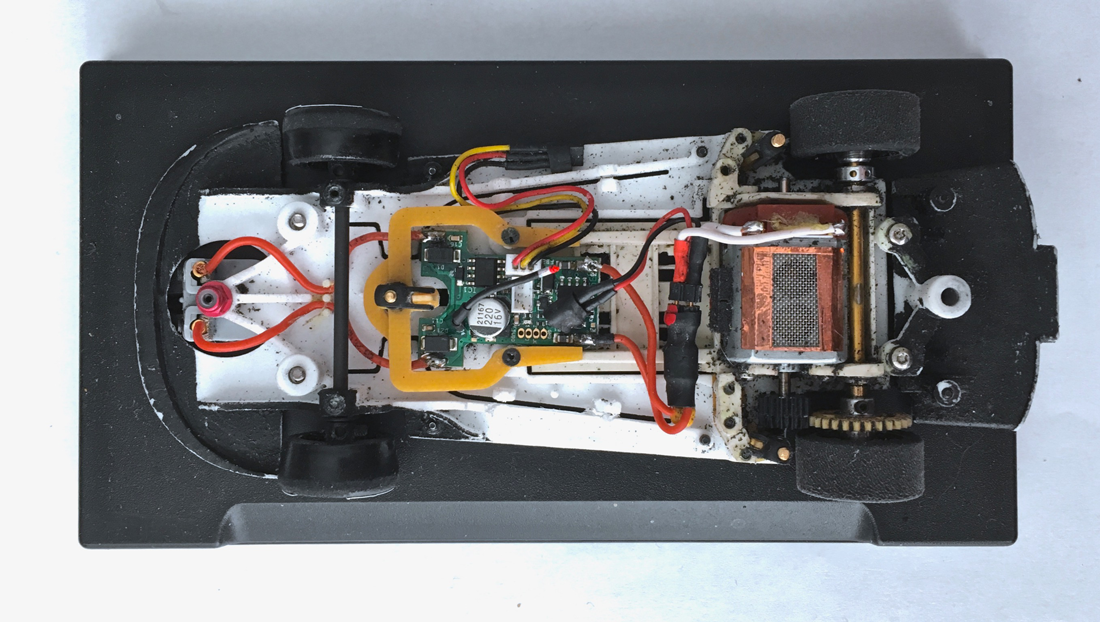

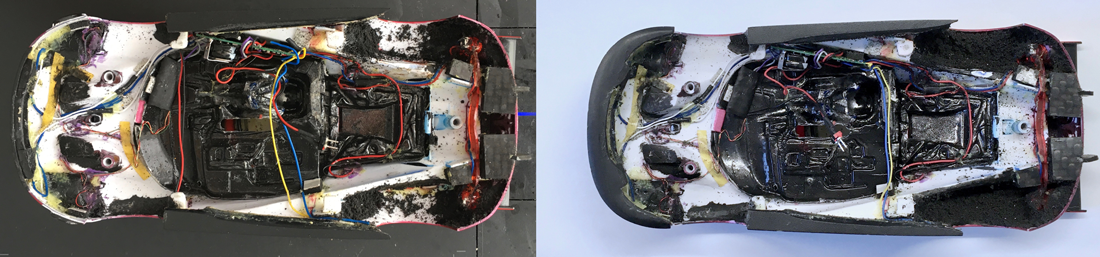

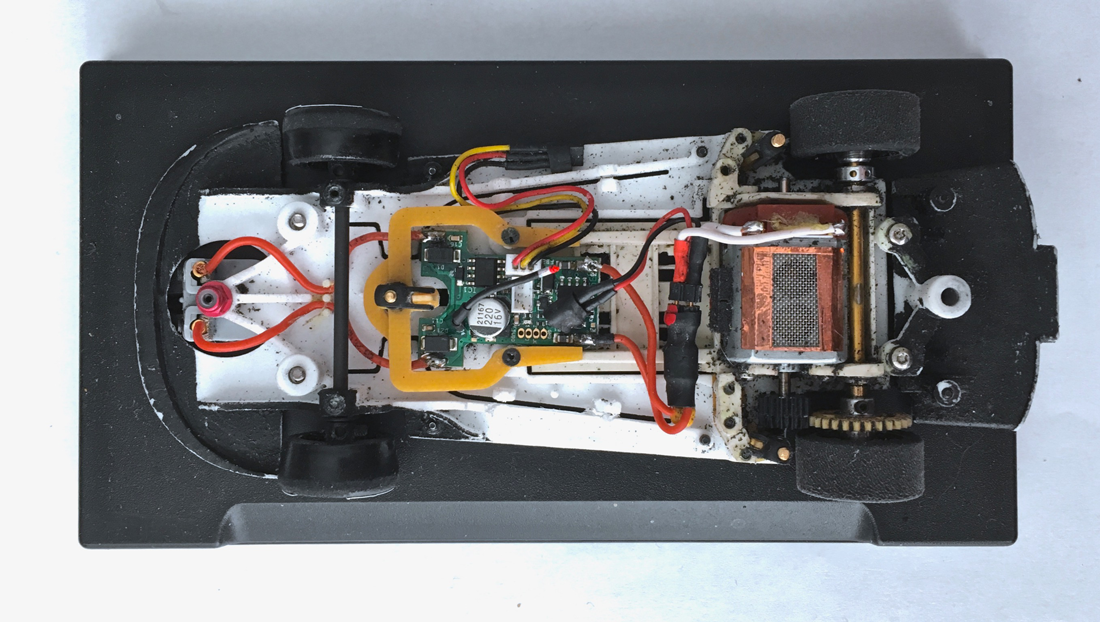

With all the post on detail bits and pieces of the Ford, I thought it would be a good idea to post an overview of the chassis "development" from

the original ProSpeed chassis via the prototype Mk1 to the now almost ready for testing MK2 chassis. 3 images representing a lot off work done in the

past 3 weeks.

On the left the original ProSpeed design which more or less had the same shape as the Scalex Ford with the side skirts and diffuser attached to the

chassis.

In the middle the Mk1 prototype where I'd cut of the side skirts and diffuser and fabricated mounting points for the body support grubscrews and the

side suspension.

This is how we ran the Ford in the first two test runs.

On the right the assembled MK2 chassis the with all the lessons learned and changes that were made "manually" to the MK1 now incorporated in the 3DP

design.

The main difference being the addition of some reinforcement ribs on the chassis to prevent the chassis from bottoming out in the middle, a different

shape for the Flex slots in the chassis with the forward grub screws moved..forward. This was to make more room for the O2 chip.

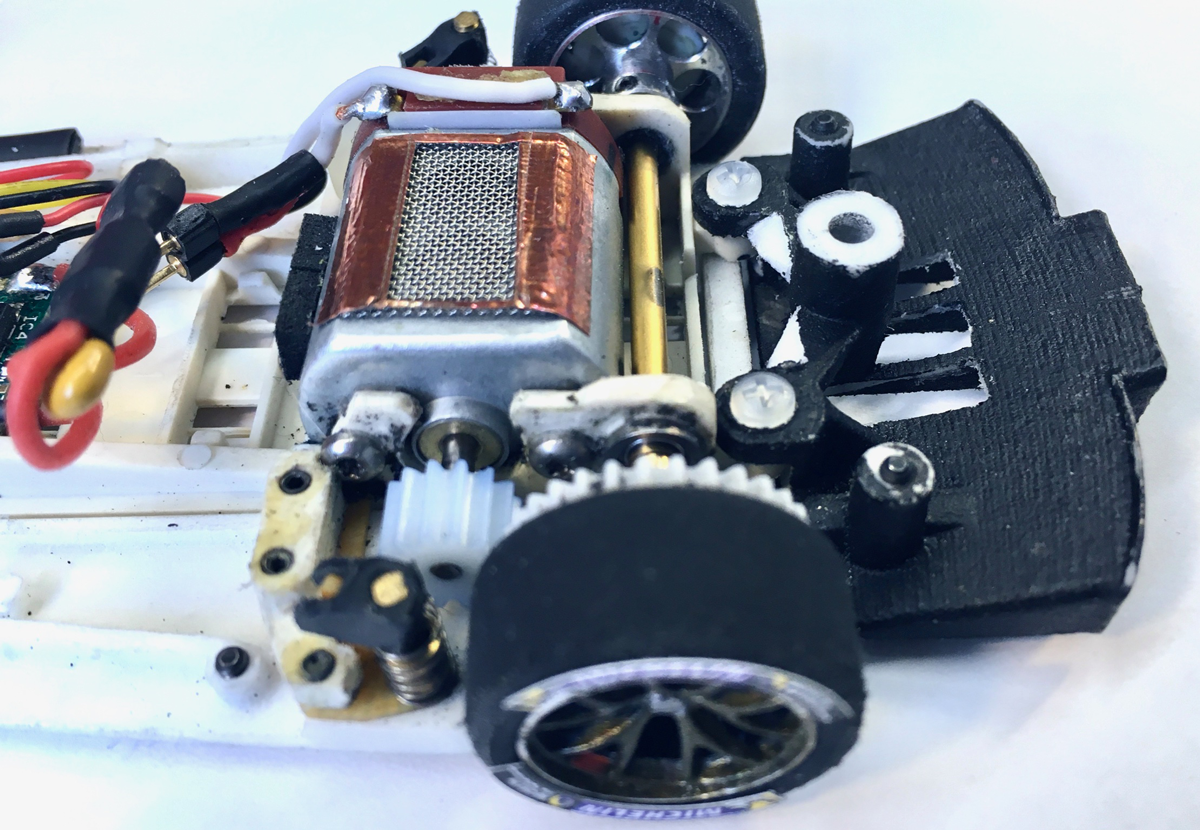

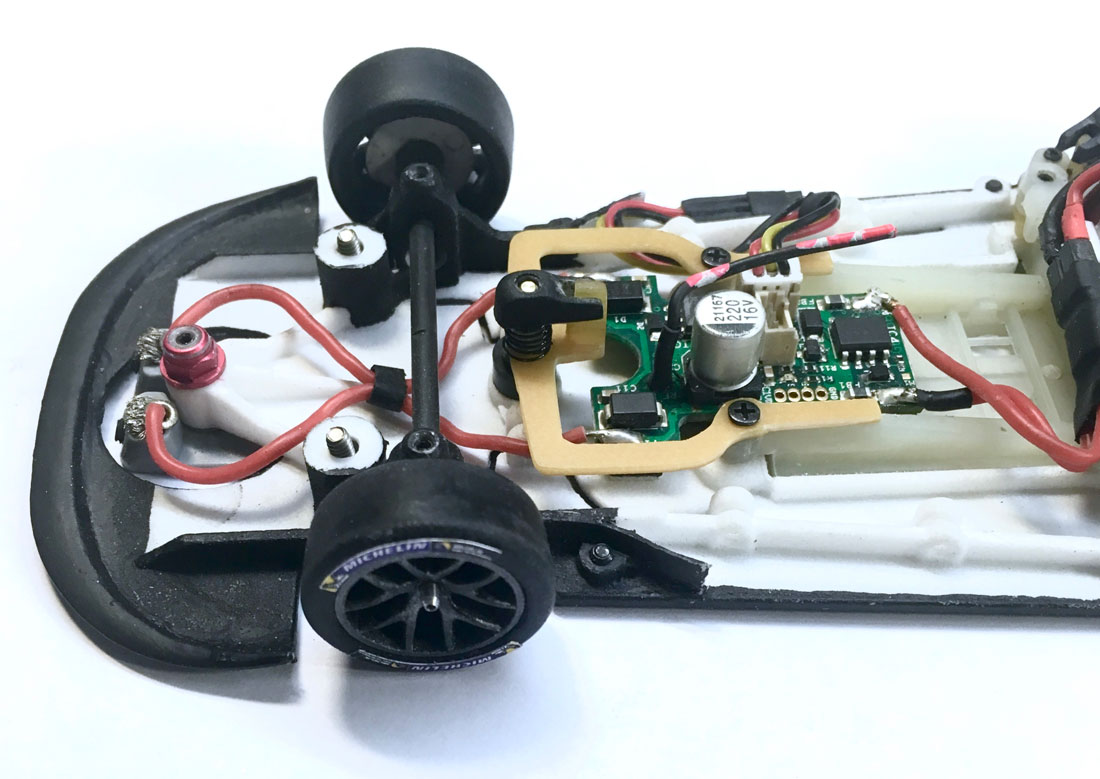

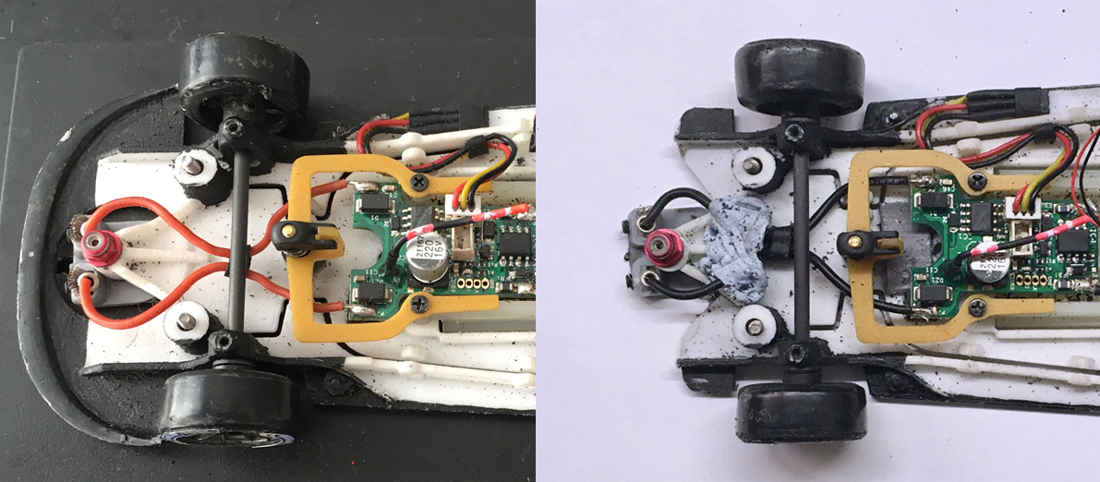

The differences between the MK1 and MK2 are more visible from below. As you can see the MK2 chassis is a dedicated SW chassis, wrapped tight around

the the Slot.it pod.

Besides the shape of the pod surround you'll also notice that the rear of the chassis has now been beefed up and now has a U-profile in which we can

glue a kevlar strand for even more rigidity and crash resistance. Just behind the front axle is the mount for the front suspension bracket (which I

still need to fabricate) that will turn the quad point slot.it pod in to a tripod.

Last but not least, the guide has been moved forward by 1mm and the guide recess in the chassis has been enlarged so we can fit the Thunderslot guide

with its wider and longer guide saddle.

2nd time around

With the 2nd chassis almost ready to run it was time to start prepping a 2nd center body section. Wasn't to happy with the first one anyway, removed

too much material and the modifications were a bit crude. But you learn from your mistakes so I.m.o. the MK2 center body is much neater and

cleaner.

Although we could in theory run the modified plastic parts....I do hope there will be time enough to cast the MK2 body centre section in silicone and

laminate at least one GRP version.

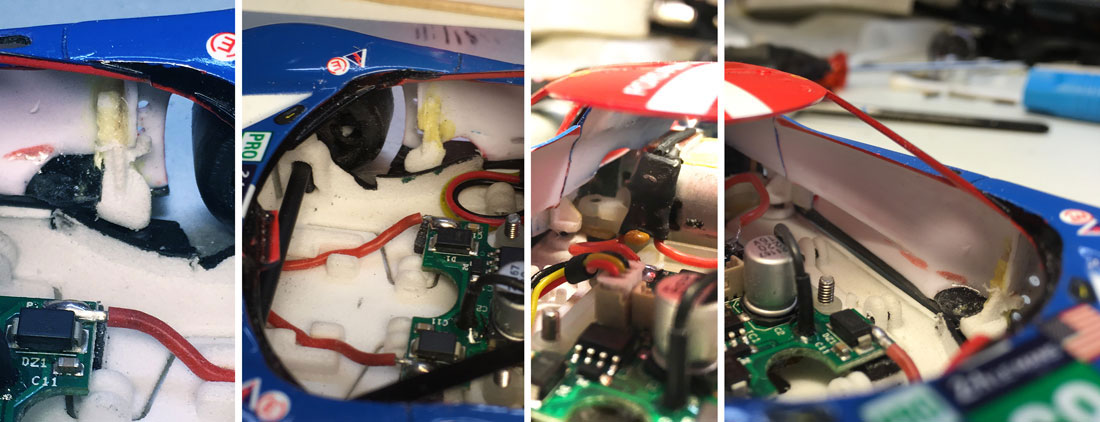

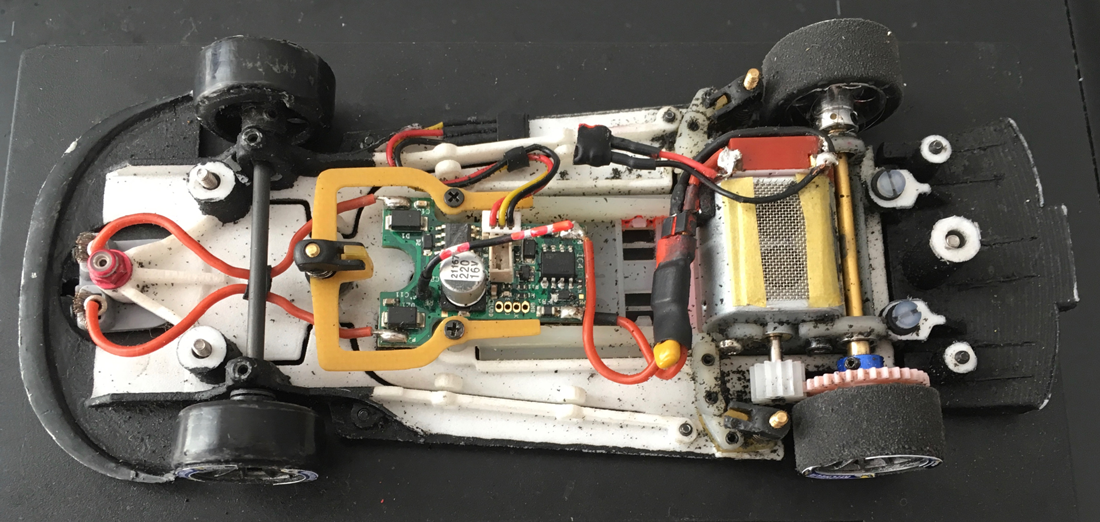

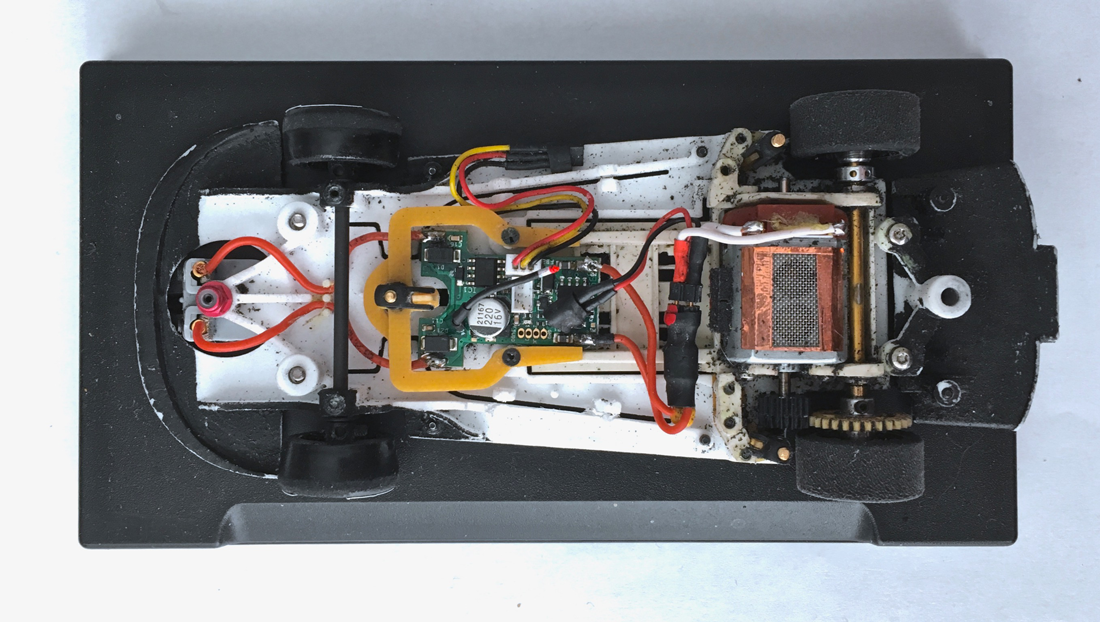

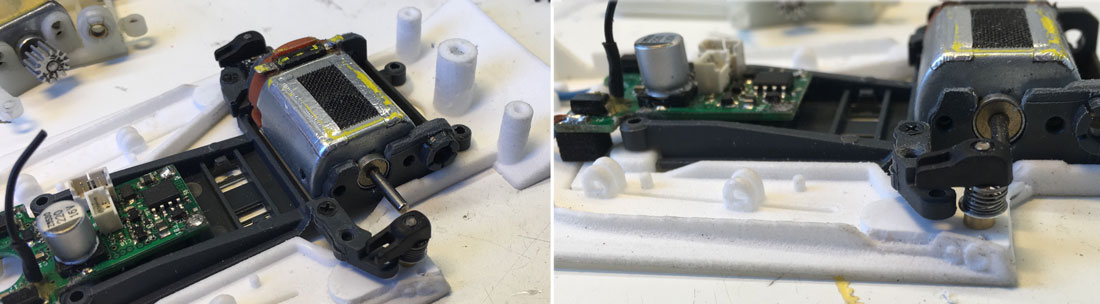

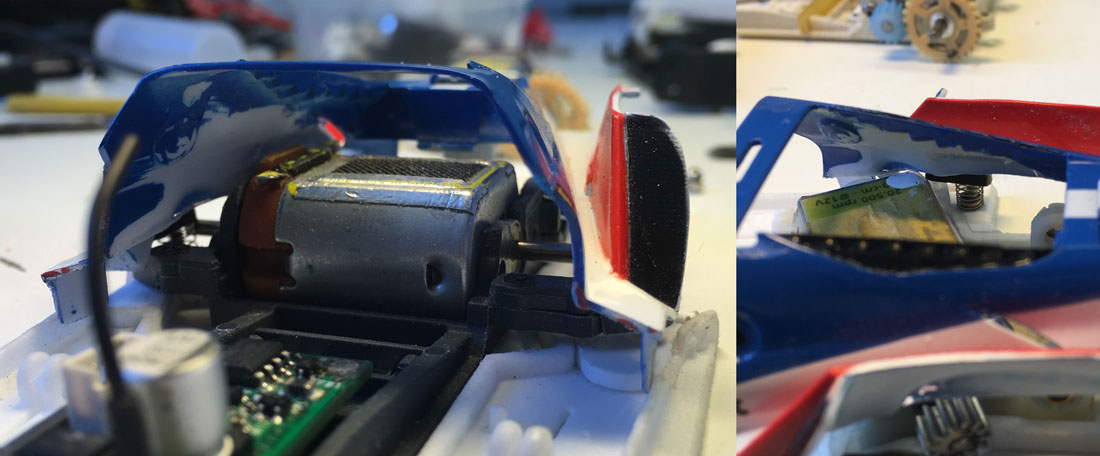

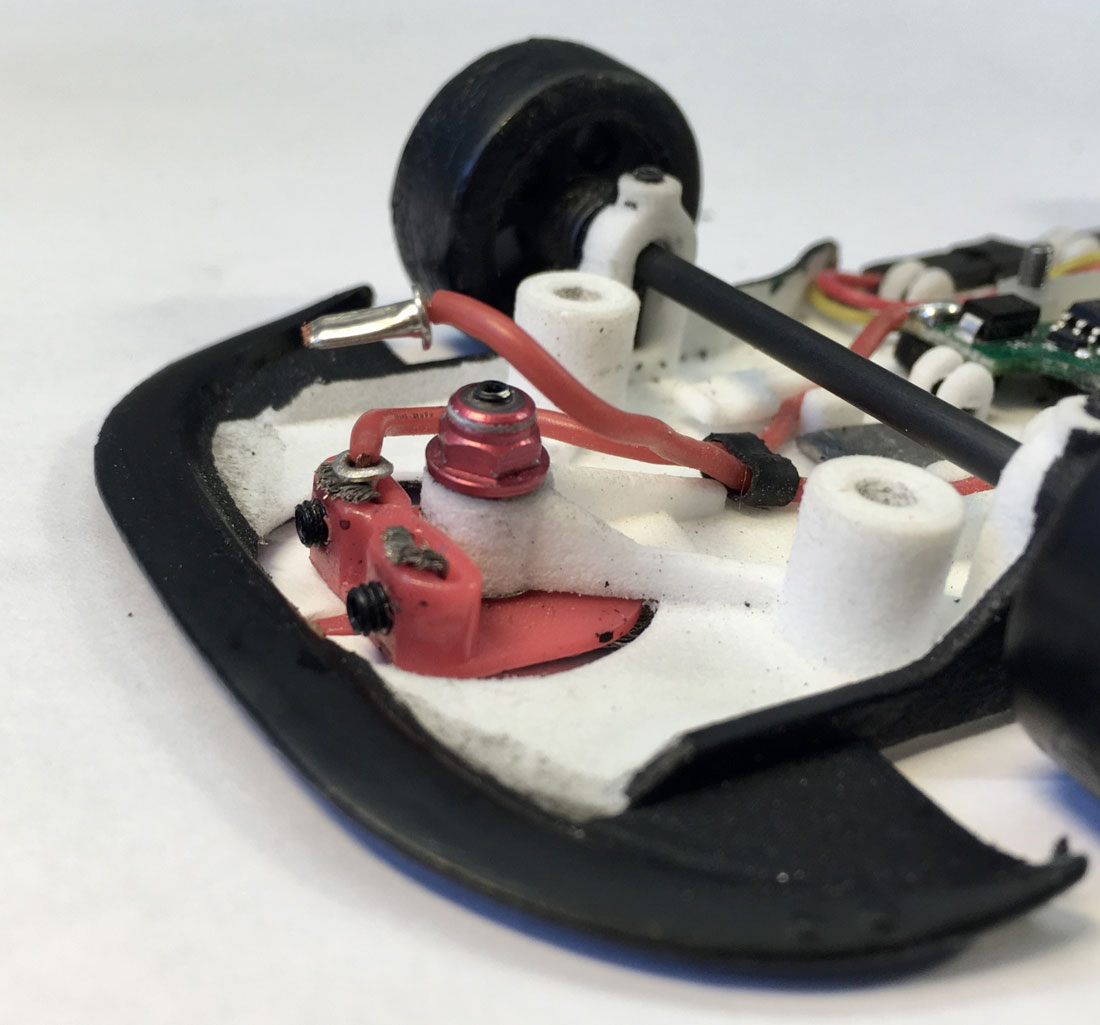

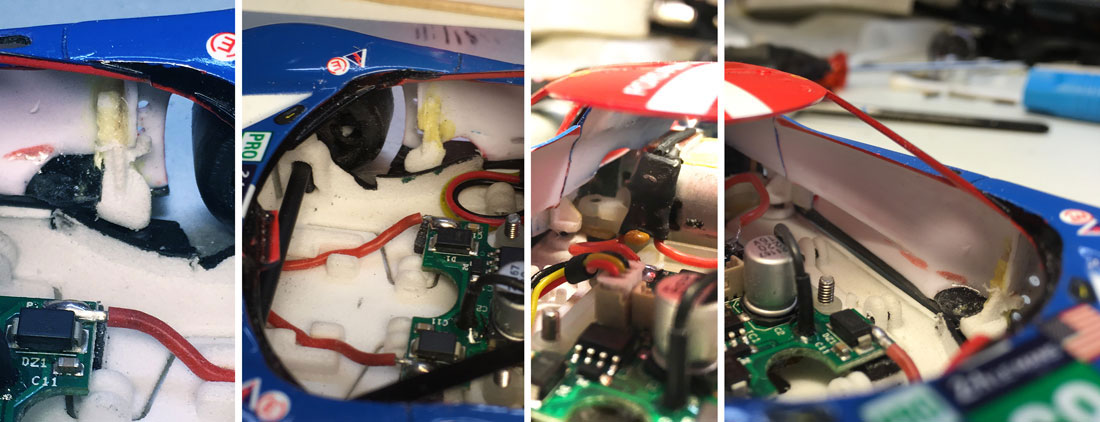

Spend a good few hours to get the motor wires, the ferrite man and the connector to the O2 chip in a position that works for both SW as AW

configuration..without interferring with the body. Here's a look "under the hood" as you can see it all fits, but its a tight fit wink.png

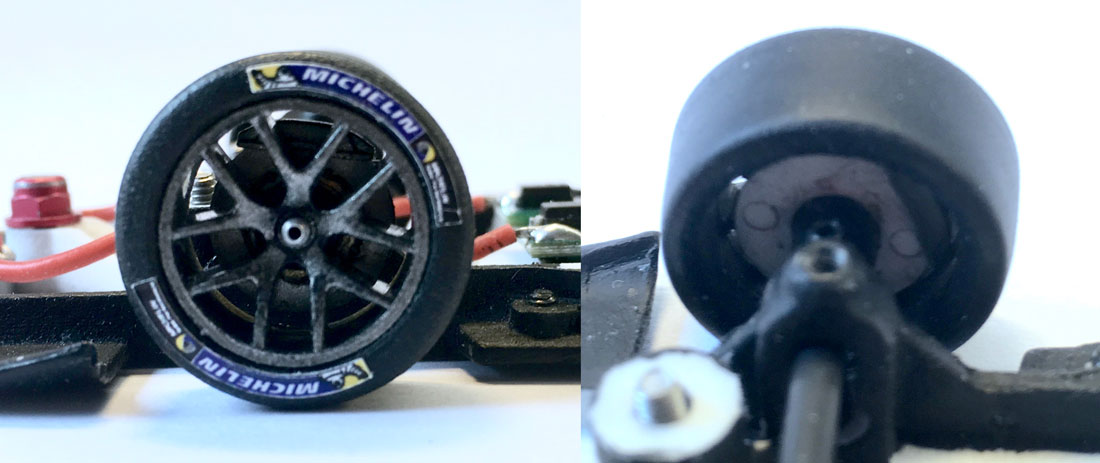

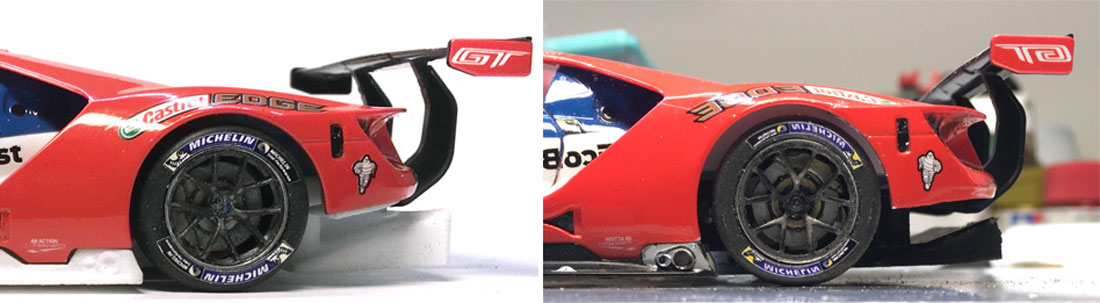

Pet project

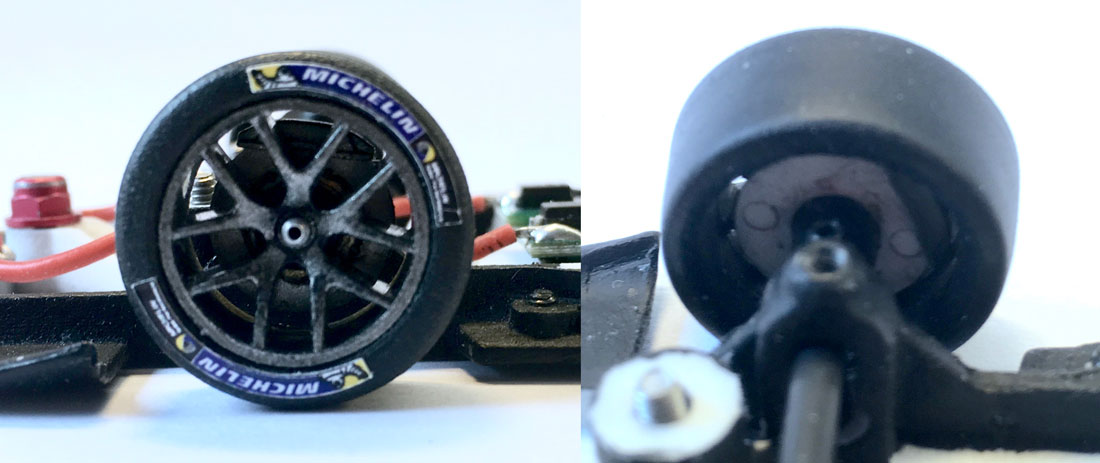

Last but not least, a bit of scale detail. I needed to make a 2nd set of front wheels for the MK2 chassis, had a good look at the stock scalex front

wheels and they are actually pretty good.

A quick trueing on the hudy and they were as good as the Delrin Sloting plus wheels I usually use. But with one difference...

...the Scalex wheel has scale spokes, no hub and insert.

Modified some Black arrow brake disc which even when "lightly' coated with paint are not totally opaque and slid them over the wheel hub.

All we need to do now to create one of my long desired pet projects...is to stick a red smd led in the hub and we could have glowing brake disks.

wink.png

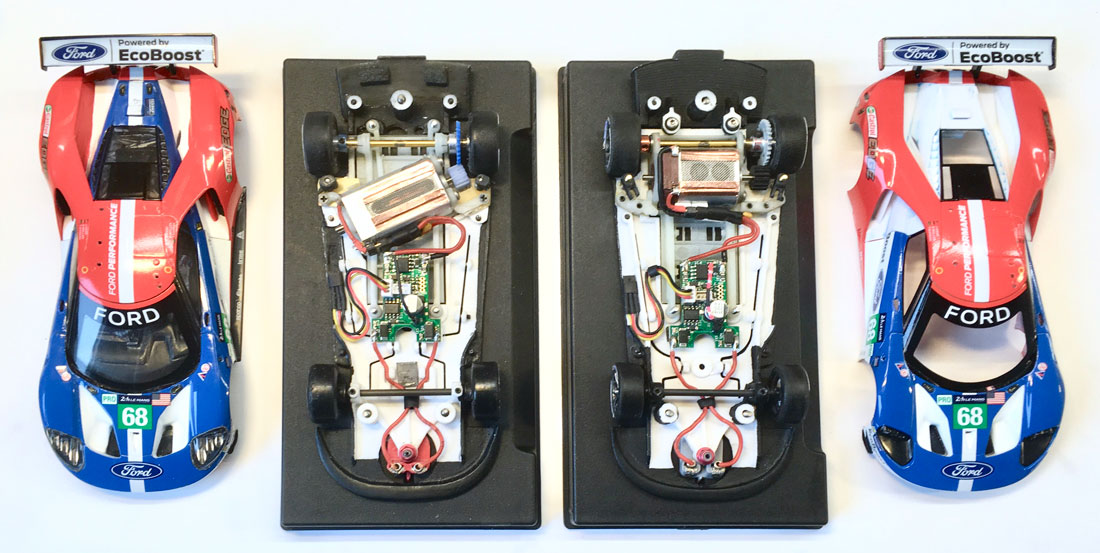

Testing 1,2,3

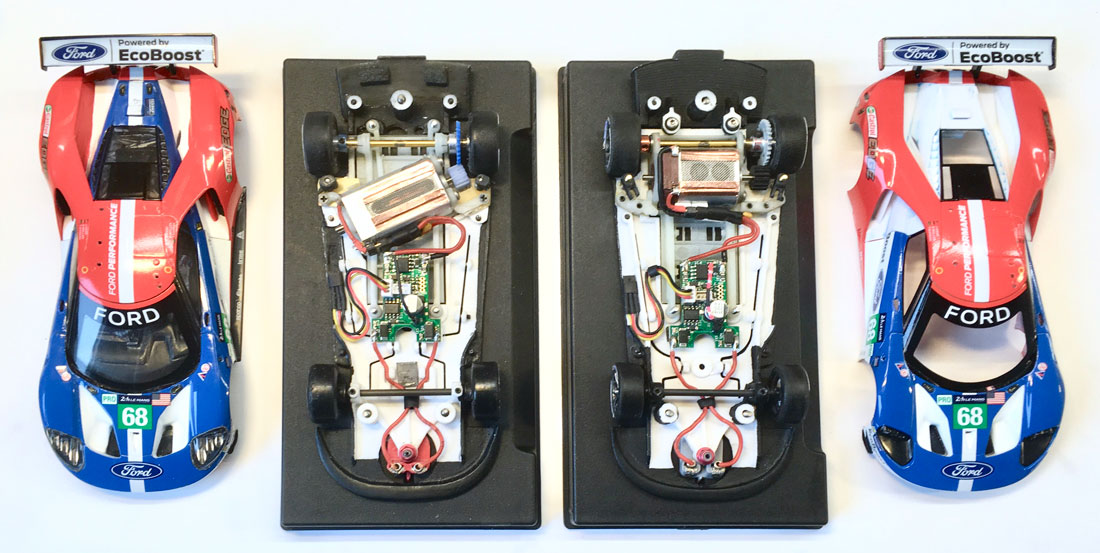

So there you have it, both Ford GT's side by side. Although the MK2 is a good step forward (at least that's what I hope saturday's test will

confirm) we'll most likely be racing a MK3 version in Henley with some minor detail changes and some extra 3DP bits & pieces.

to be continued...

Big Al - 11-3-2019 at 12:41

tamar - 13-3-2019 at 01:55

The Road to Le Mans 1/32: 3 weeks and

counting

Just 24 days before the start of the first practice session in Henley in Arden. Looks like we're going to play catch up with Garage 27 for

car prep. We've had a good test session last weekend in which we managed to do a lot of work and testing, not everything I had hoped we could do,

but it was a very, very constructive day.

First and foremost, we've now got a good base set up for the new MK2 chassis, that may look easy, but with a new chassis you basically start from

scratch for 50%. And one those test days..time flies. But I'm getting ahead of the story, more on that part in a later post, because before we could

go testing I first had to finish some parts.

Bussy Bees and Lego

time..again

Marc was going to bring the Dental Vacform machine to Best (thx Eric) so we could pull some lightweight windows, meaning that I had to prep the

masters.

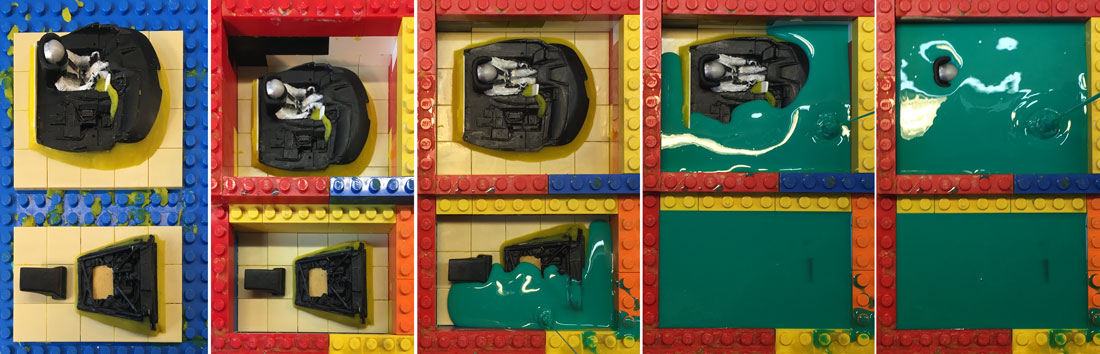

So here I go, its lego time again. Besides great for building the walls of your cast box, the little Lego pieces can also be used to support and

fixate the position of the part you want to copy.

Most important when they're fragile breakable parts like windows, even more important when those windows need to be fitted from the inside of the

body..to maintain the correct shape and fit.

On the left image you can see how I used some Lego blocks to build up a base. In the centre image you can see how I then applied the Modeling bees wax

around the Lego base. (sorry, a bit out of focus)

You can actually see the top of the Lego sticking out of the bee wax.

The Bee wax can be shaped cut and moulded with a knife, a spatula and even with your fingers. Its great stuff.

It gets softer when warm and can be dissolved (as in when you need to clean the master again) with cleaning petrol.

When building up the bee wax you need to pay attention to three things:

1 that you seal your master completely, because even with the tiniest small gap between the master and the wax...the silicone will creep in

between.

2 that you keep the master as pyramid shaped as possible.

3 that you maintain a clear definition on where your master ends, if needed you may need to go against the pyramid rule here, as long as the overhang

is minimal.

After bee waxing its time to build the cast box, and the to clean your master, and I mean clean, polish and remove every flint or dust particle that

you can find.

Because the silicone will copy anything, even the tiniest surface details like lettering on the window streamer or the tiny raised window frames that

Scalex tamponed on the glass...

...which in this case isn't such a bad thing... but that too is for a later post.

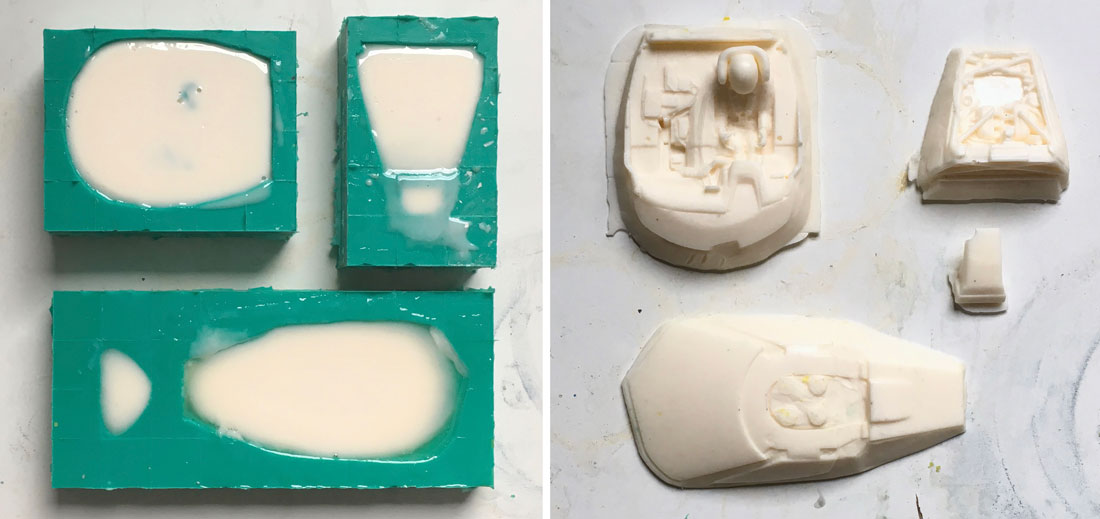

Casting bubbles and how to get rid of

them

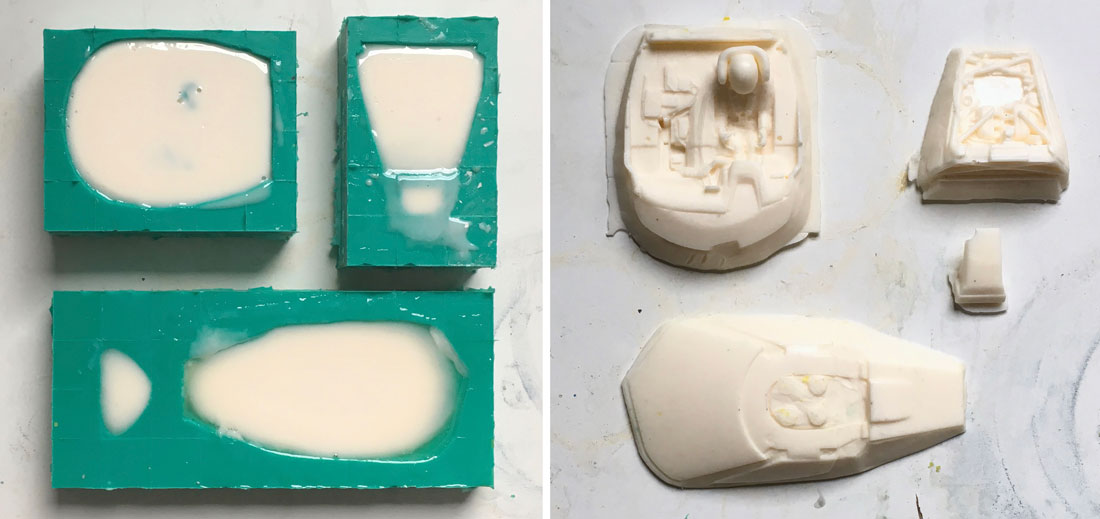

I've covered casting the silicone before so I'll skip that part and head straight to the resin casting. Here (also due to time restraints) I used a

very fast setting PU resin.

Handy when you want to pour several casts in a couple of hours, but the down side of the fast stuff is... you've got a two minute window in which to

mix the stuff and pour it into the silicone.

As with silicone casting the main thing to avoid here are air bubbles, they are unavoidable (well with out a vacuum pot they are) but there is a

(quick) work around to get them out of the important parts...

.. and those would be detail parts like the thumbs and fingers of your driver or some delicate motor detail that took you hours to create on your

master, or the bottom (and thus in the mould the top side) of your air intake.

So before you start mixing your resin, have you silicone moulds laid out in sequence of casting, have a fair amount of kitchen towels ready for the

Oooops! :wacko: moments.

A spatula to wipe off the excess resin and most important..a couple of tooth picks.

Now you can mix your resin, make sure you mix the minimal amount, as the more resin you mix in the cup the shorter your cast window will be. Don't

worry about mixing too little for these type of masters.

Resin sticks to resin like....well that would automatically be corrected here on SF, but believe me it bonds very well. So even when your mould isn't

filled to the edge, just mix a bit more and complete the casting.

So..about the work around to get the worst bubbles out...well its simple, as you can see in the pics above I use the tooth pick to pry them out of the

deep parts in the mould.

Just stick it in the cast resin while its setting and wobble it around... sounds simple doesn't it ?...

...well off course it isn't that simple and it will take you several casts before you get it right as can be seen in the picture above right.

Took me several pours to get one air intake without some air bubble caught in the mould. But the windows and headlight lenses came out perfectly.

Ready for some Saturday afternoon vacforming.

Front suspension from quad pod to

tripod

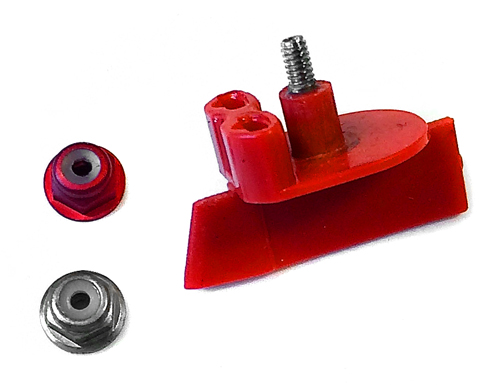

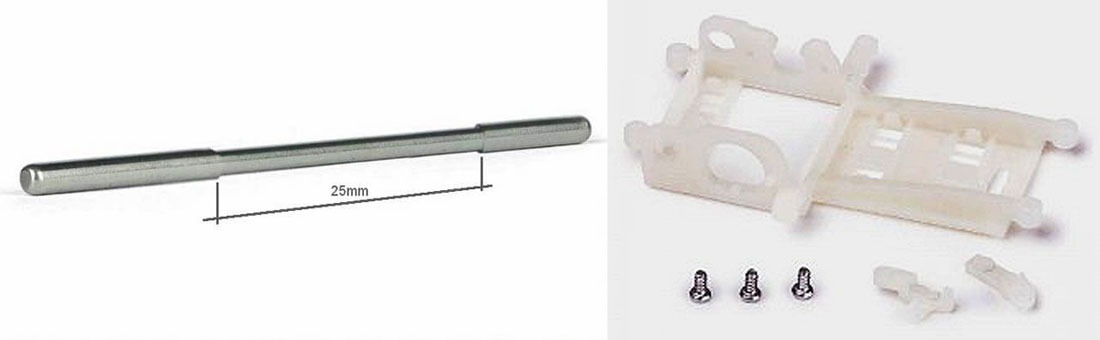

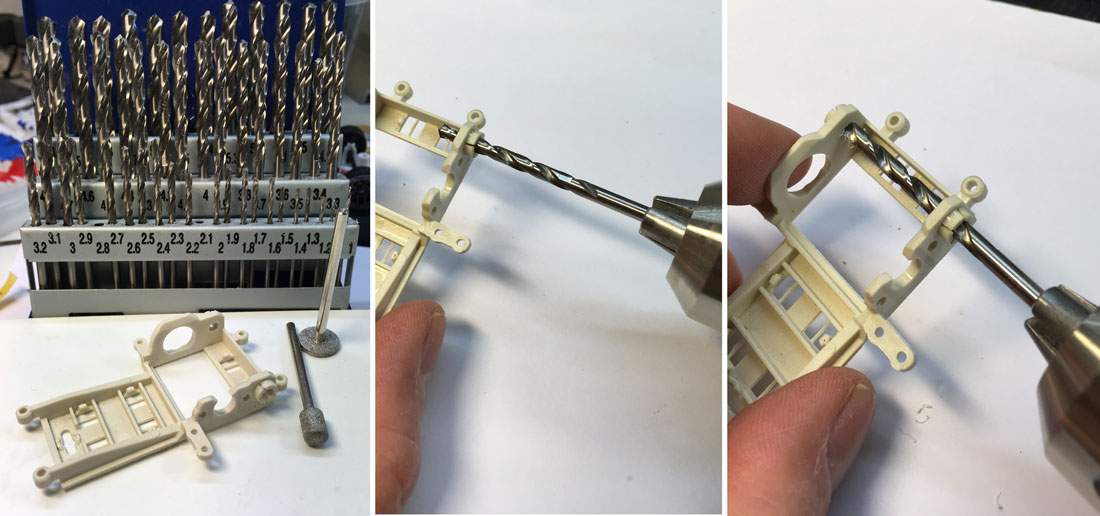

There was one more item that I had to fabricate for the MK2 chassis and that was a bracket to mate the Slot.it SW pod to the central front suspension

mount we'd incorporated in the MK2 design.

We'd used a similar design last year with the C7R for which Stefan Kievit designed a nice 3DP part, but although it worked very well, that bracket

needed to be dis mounted from the motor pod if you wanted to change the O2 chip.

For the Ford I wanted too keep it more simple, stronger and lighter. So I rumbled through my supply of GRP and cut this small (and if I may say

elegant) bracket from a 1mm thick sheet.

A Big head tall Slot.it suspension screw, some spacers and a 2mm bushing, a short Scaleauto spring and a Thunderslot top nut.

The Slot.it SW motor mount had now been modified from a quad pod to a tripod with just on screw to set the front pod float, which can be done without

taking the body off.

Now we were ready for some serious test runs.

To be continued

p.s. Hi Al good to see you back here..wie het kleine niet eert

tamar - 14-3-2019 at 22:41

The Road to Le Mans 1/32: 3 weeks, some Team

news-updates

In just 21 days we should be arranging all the tables, chairs and the Marshalling floor mats @ Warwick college sports hall in Henley in

Arden.

With all the time and effort it takes to set up the 1/32nd DiSCA La Sarthe track a helping hand is always appreciated.

Alex and Gary have a place for every bit of track and scenery firmly locked up in heads...(a couple of thousand items, but they do have a written

manual to fall back on)...so we'll just be taking the dumb and heavy work of their hands.

Took a few nights off working on the Ford's, also needed time to catch up on posts, pm's, emails etc etc. One of them lead to a very interesting

bit of team news

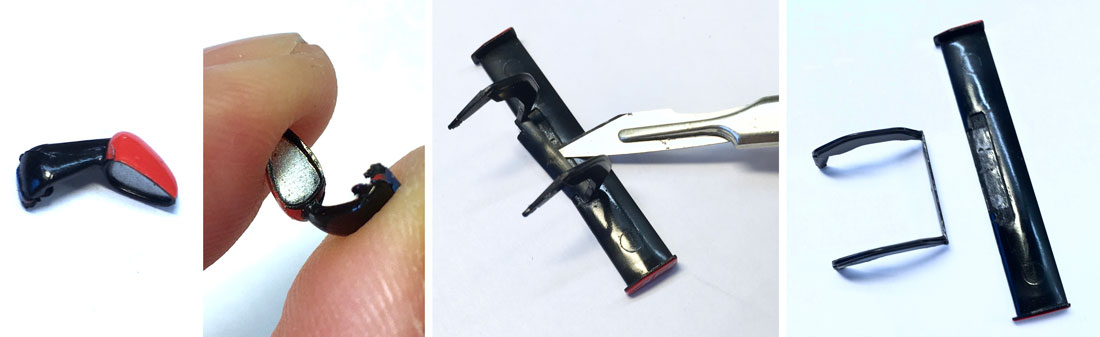

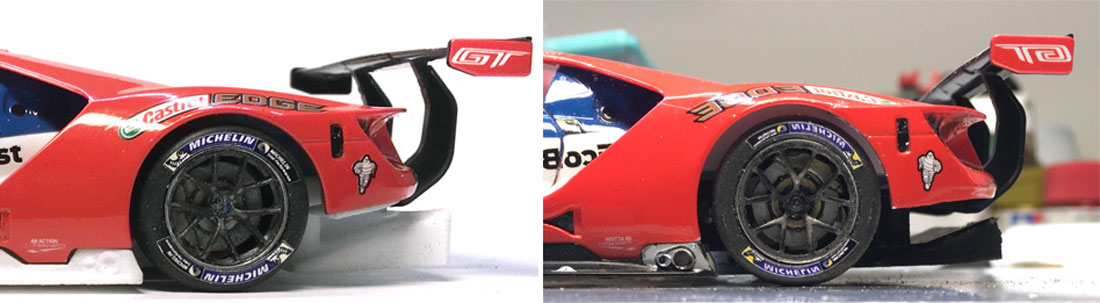

Scalextric detail parts...

As I mentioned before the Scalex Ford is a very nice and detailed car with some nifty design features to prevent breakages in case of a crash

(well..with exception of the aerials)

Before I start my builds I usually dismount all of them and store them safely in a box for later mounting or to use them to create masters for rubber

casting or vacforming.

To be honest I had a very hard time trying to get the mirrors off the body (as I wanted to recast them in rubber) noticed that they were quite

flexible and upon closer inspection found them to be cast...in rubber!

Now that was a big time saver and it's a real pain in the "buttocks" to paint rubber nicely, so here a feather in your cap, way to go

Scaley.:thumbsup:

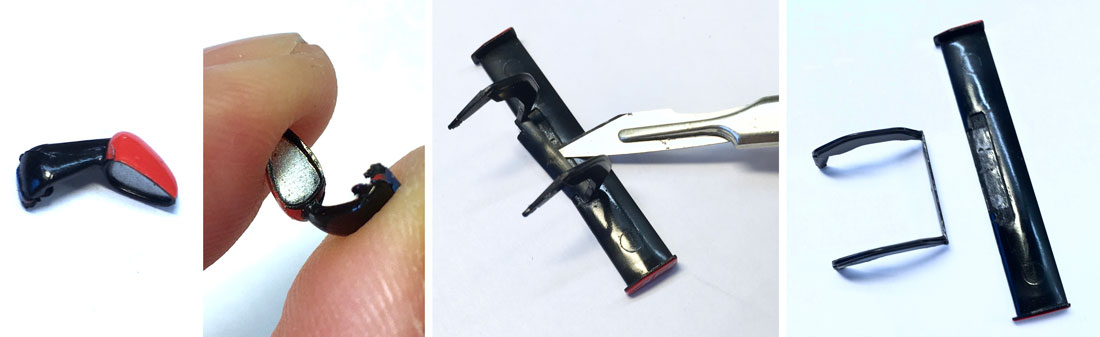

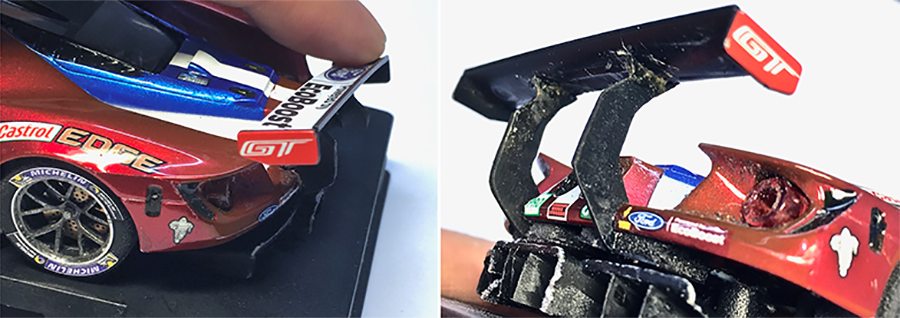

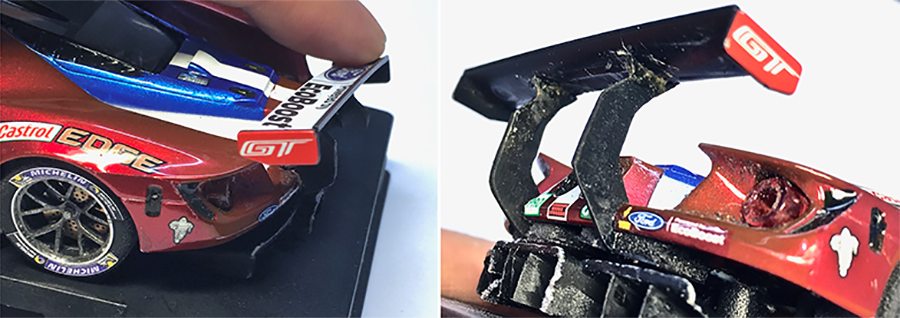

For most of you that have acquired a Ford one of your concerns might be how to keep that delicate rear wing sticking way out the back, on your car..in

a crash...

Well you shouldn't ! You should allow it to come off..at least in a hard crash.

The rear wing has been designed as such that it clips into a mount and would come off in a hard crash..if not for a tiny drop of glue added in

China.

But that tiny drop of glue actually prevents the wing supports to come free in a hard crash and may result in breakage.

So stick a thin scalpel next to the supports into the wing mount and wiggle to cut the glue and you're home free...but there's more.

Once you have the wing off the car and flip it upside down you'll notice a seam line and that its actually cast in two parts: the rearwing supports

and the top wing with the endplates.

So again, take out you thin scalpel blade and carefully, and I do mean carefully (as in always point the sharp end of the blade away from you) try to

pry it between the wing supports and the wing.

Now on two of the three wings I have treated this way there were only small dabs of glue used to fix the support. I could easily pry the blade between

them in the middel and wiggle my way with the scalpel to the sides and the wing would come off.

But with one wing someone in China had been really thorough and more generous with the glue, couldn't get the blade in between.

In that case I would advise you to leave it as it is and "just" be content with the "clip in" safety. But if you can separate the wing from the

support and clean the recess from glue.

Just a tiny bit of thin double sided tape or a small dab of shoe goo will give you an added safety feature to prevent breakage in case of a serious

crash.

...and Scalextric after sales

service

Ok so back to that PM I had send, the one leading to a nice bit of team news. DiSCA sporting rules require all detail parts to be present on the

cars.

Small detail parts (like mirrors and wipers) only need to be present at the start, but wings need to be present at all times.

Should they come off you'll get a notification from Race control and you'll need to Pit within 5 laps to replace it.

Which (if your car is prepped for it) should not be a problem as by that time..a Marshall will kindly have placed the part in the "lost & found" bin

at RC.

And if the Marshall is bit a slow, you mount the spare and place the retrieved item in your spare parts box in the Parc Fermé... later.

This procedure works well in the day time...but in the night darkness.... it may take a lot longer before the "lost" wing is retrieved...and some

are "lost" ...forever.

So it is handy if you have at least 3 or 4 spares.

So Tuesday evening I send a PM to the only Scalextric rep I know, well at least I knew he is a SF member. I modestly asked if he could maybe act as

a liaison...

... and ask Scalextric if they would be willing to "support" our effort with 2 or 3 spare wings and mirrors.

Got a PM back the next morning with a reply that Scalex really doesn't have any facility to supply spares. But, to drop him an email with my contact

details...

...and he would dig round the office and to see if they had any spare shells etc. etc.

In the afternoon I got an email that he [/size]couldn't source any spare shells, but that 3 complete cars were now laying wrapped and ready to be

shipped out in the post room.

Way to go Scalextric, that's what I call "after sales service" You ask for 3 wings and mirrors and you get 3 complete cars, it was

like Christmas all over again.

So as a thank you the Ford MonkeyTown Team NL cars will now proudly carry Scalextric decals on their bodywork. :thumbsup:

And while we're talking decals, here's an other Team update: on the roof we'll also have decals with the names of Wayne and Stephen Lander listed

as drivers of the #18 car.

Regardless of how Brexit will end..here's to another Anglo-Dutch cooperation :cheers:

To be continued

tamar - 18-3-2019 at 08:44

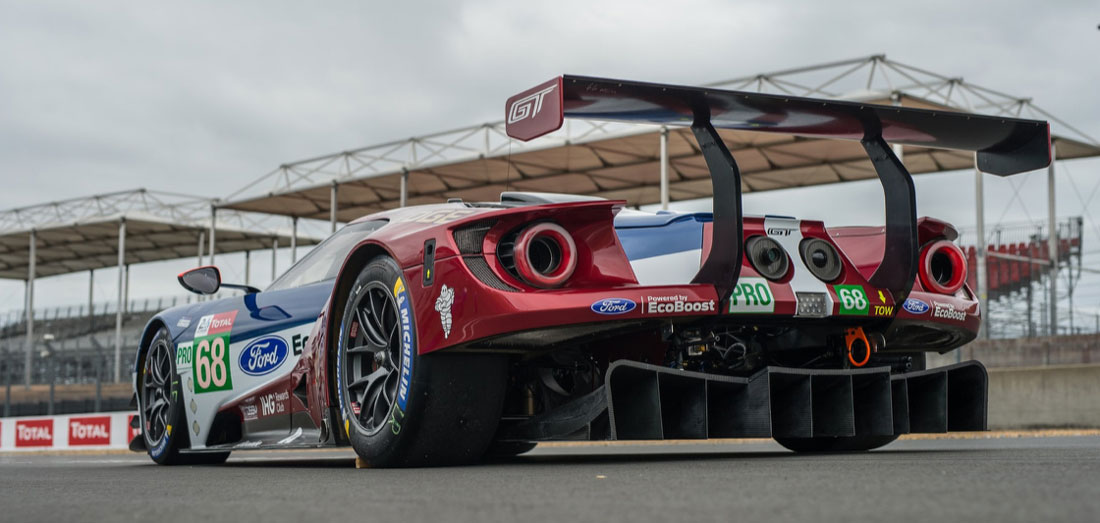

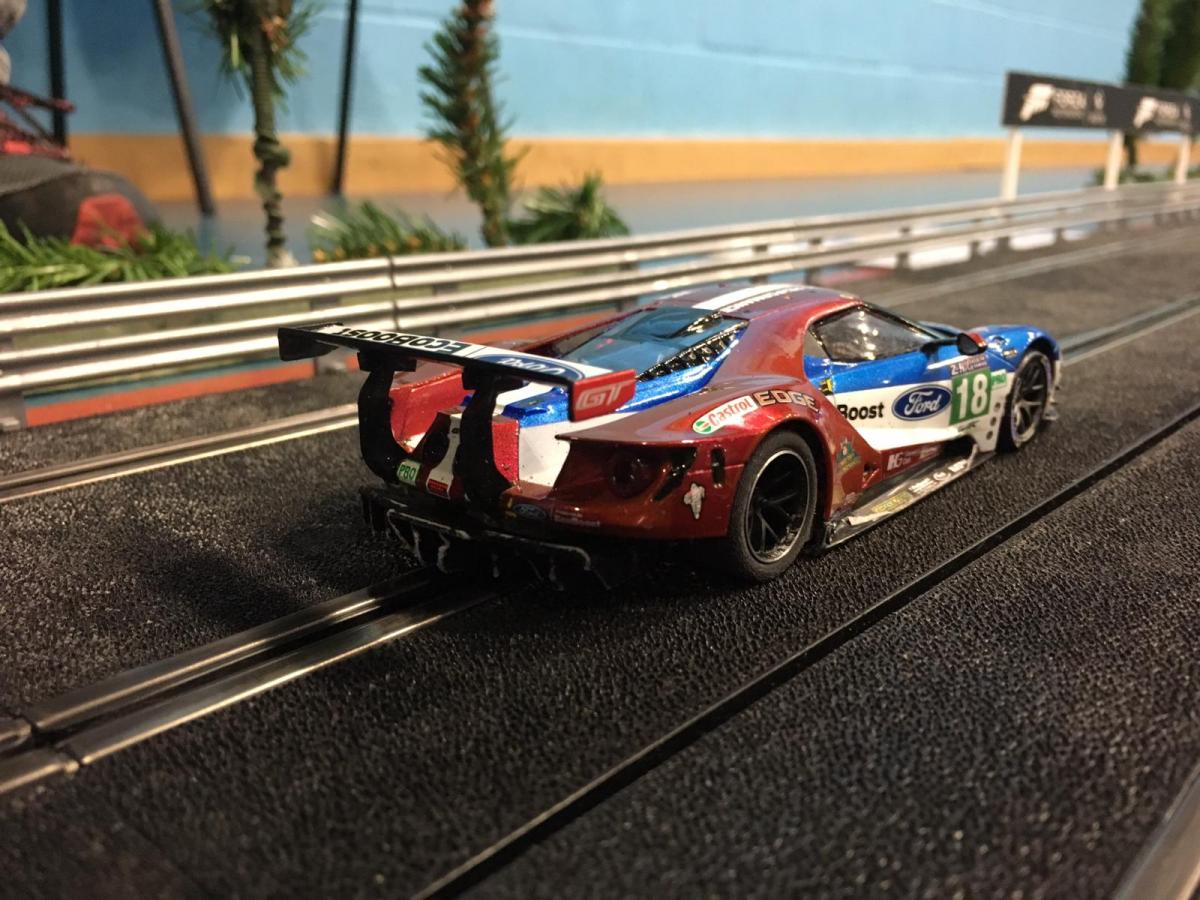

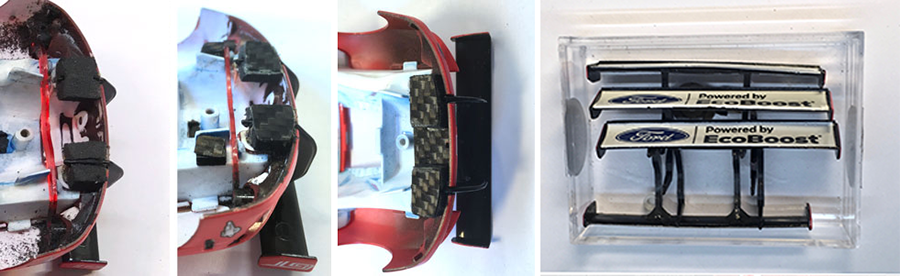

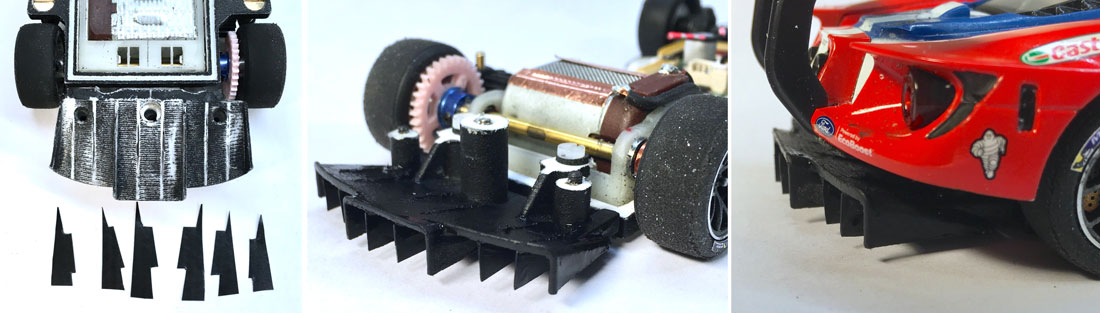

Spotting the tales of Tail-end Charly

So with me taking a bit of time off watching motorsport, not much work has been done on the car this week, but..there's plenty of stuff I have not

posted yet. One of the things I'd thought at least someone to notice, was the work done at back of the car. I mean there were more than enough hints

in some of the pictures I posted. But apparently nobody dared to ask what I had really done to my Tail end Charly...the huge diffuser sticking out the

back of the Ford.

Ever since the ACO/FIA/IMSA aero rules changed a couple of years ago diffusers, almost bigger than those seen on LMP's have become a trade mark on

the GTE/GT-LM class cars.

And as such they've started to appear on slot-car models. Not that much of a problem on a stock chassis, but as we learned with the BMW M6 ....they

can get you into trouble on a podded chassis with lots of suspension travel.

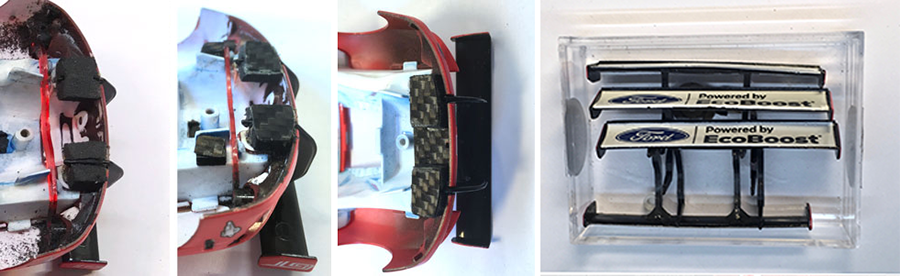

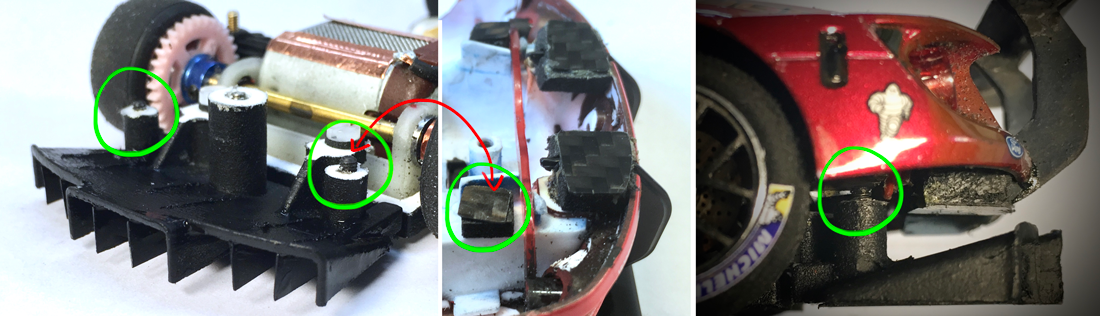

The wishbone's connected to the collar bone, the collarbone is

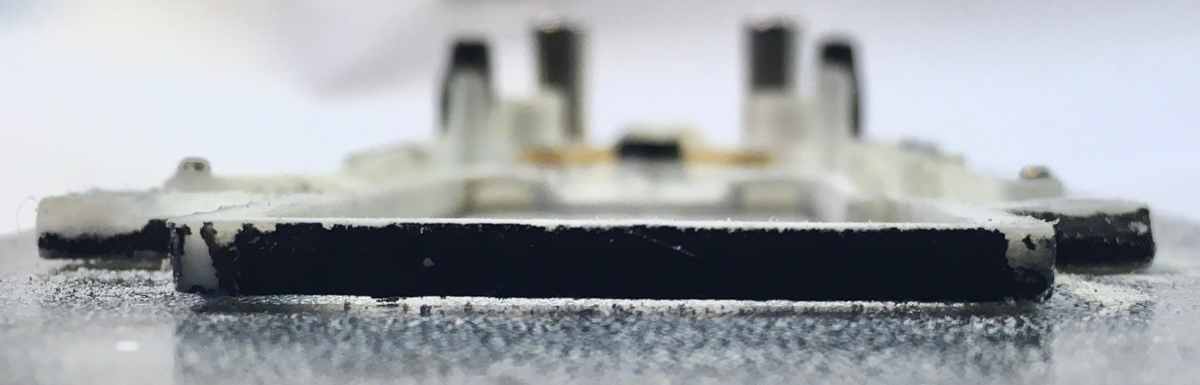

connected to?

On a podded chassis with suspension, you max amount of suspension travel should ideally be smaller than the ground clearance your running. Other wise

you chassis will rubb the track. No matter how long your screws are or how tall you springs are...your looking at 1-1,5 mm of travel max. But as the

back of the chassis sticks out behind your suspension mounts...a small the amount of travel at the suspension mounts will be translated in to a bigger

movement at the back. Meaning that if a lot of chassis is sticking out at the tail end...like on the Ford...it will be rubbing the track way before

you get near 1,0mm of travel.

So somewhere in early februari, I'm working on the chassis side suspension, fiddling with the motor-pod, mounting it to the chassis for the umpteenth

time. To keep the pod in the correct position for me to drill the holes for the suspension screws, I fully tightened the rear pod screws.....and then

it hit me! With the pod now firmly connected to the chassis and the rear diffuser behind it... no movement between the two parts, the diffuser was

just as much connected to the pod. What if.....

So at the end of first shakedown on Sunday feb 10th there was one more test we needed to do. The "What if" I wanted to test was how the handling of

the chassis would be influenced...if the diffuser was not connected to the chassis but mounted directly to the motorpod.

As this would be a "no way back" kind of test, we first tested if the handling of the car became worse with the rear pod screws not connected to the

chassis at all. The handling of the car remained the same...all we needed to do was ad some extra spacers inside the springs to limit the suspension

travel. Ok ..so far so good, next step.

Now it was time to cut the back of the chassis off and mount it fixed to the motorpod. Immediately we noticed that even with the full amount of

suspension travel the diffuser was no longer rubbing the track.

Yeeeeeeeeeeehaaa

With a big smile I added the pod mounted diffuser to the number of modifications to be discussed the next day with Stefan Nalbach to be incorporated

in the MK2 chassis design.

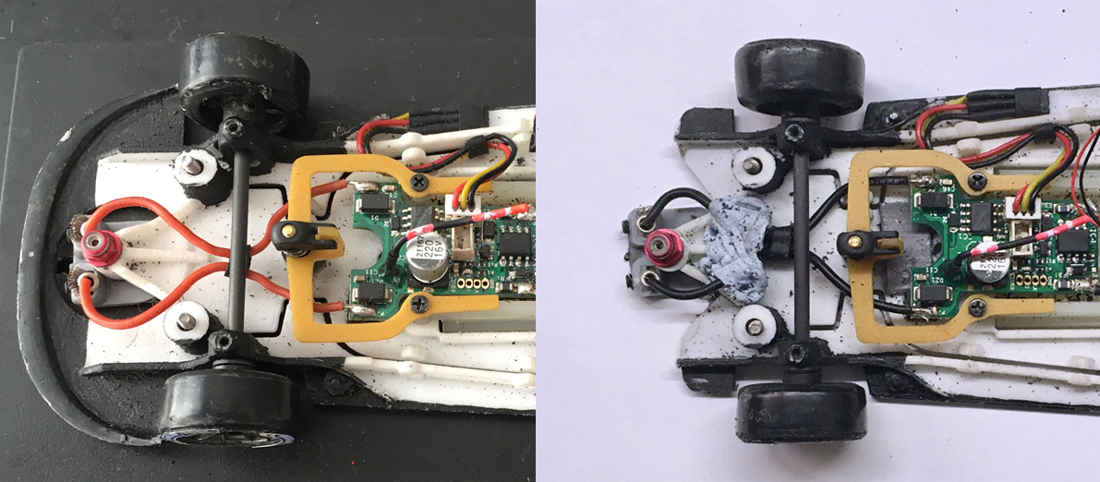

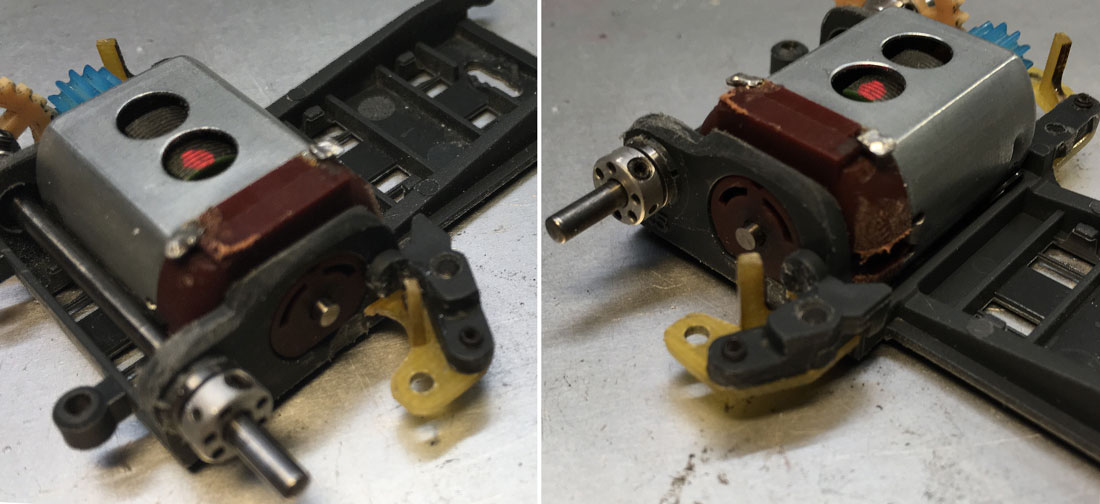

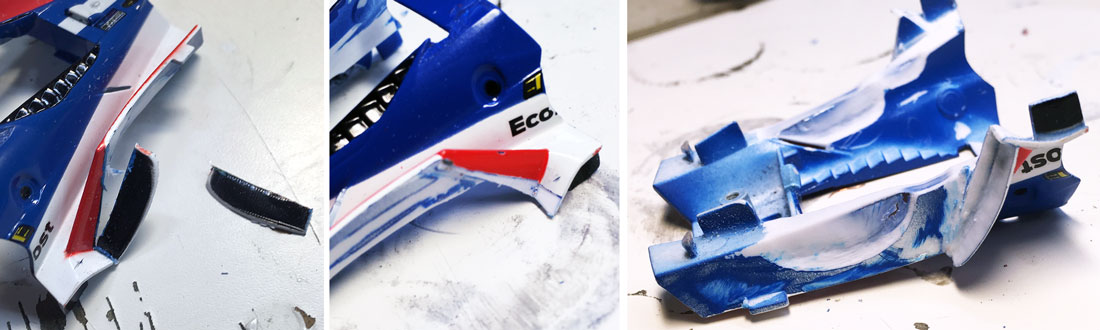

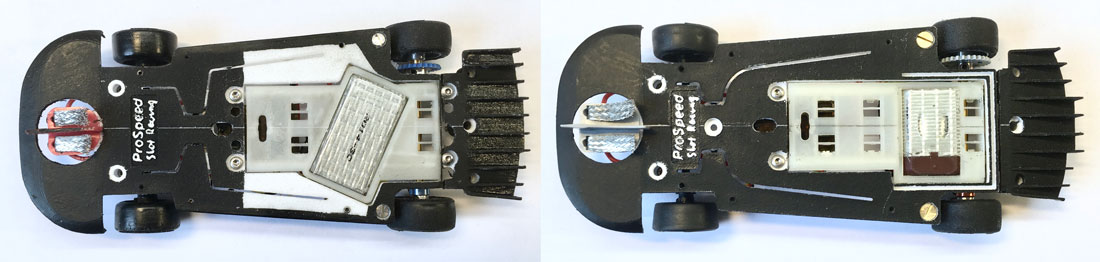

On the left the diffuser cut of the prototype MK1 chassis here the diffuser was still

mounted with screws from the bottom, on the right the MK2 version with the top mounted screws. Rubber washers were added for e bit off extra

flexibility in case of a hard hit to the rear of the car.

to be continued

tamar - 6-6-2021 at 11:30

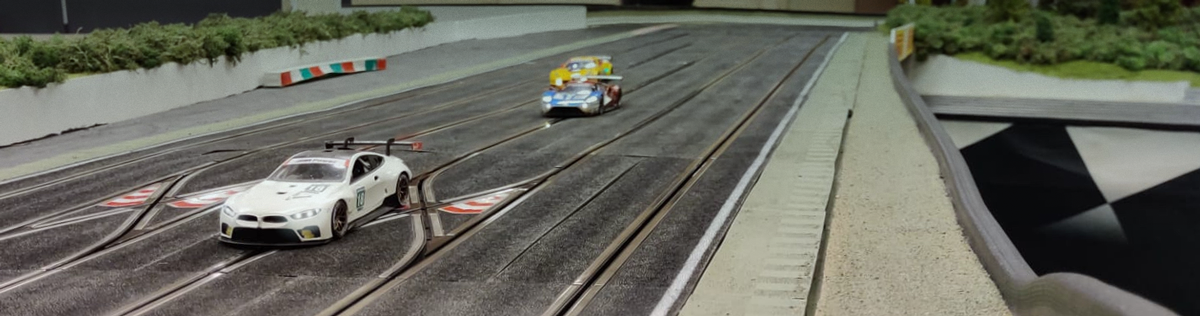

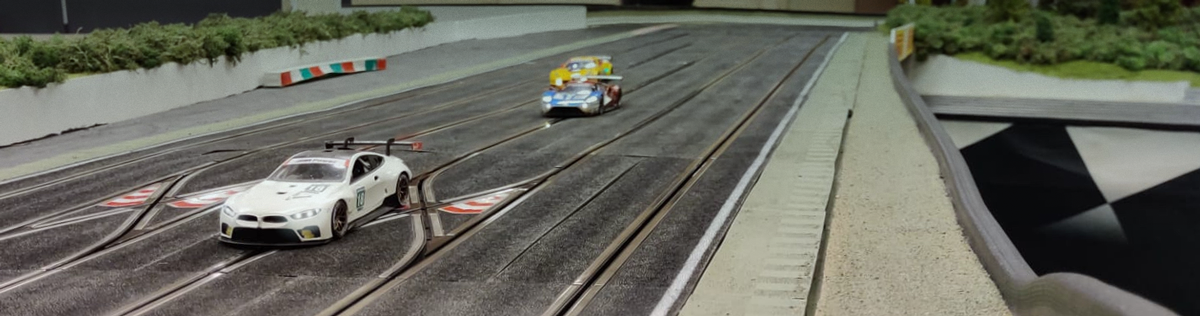

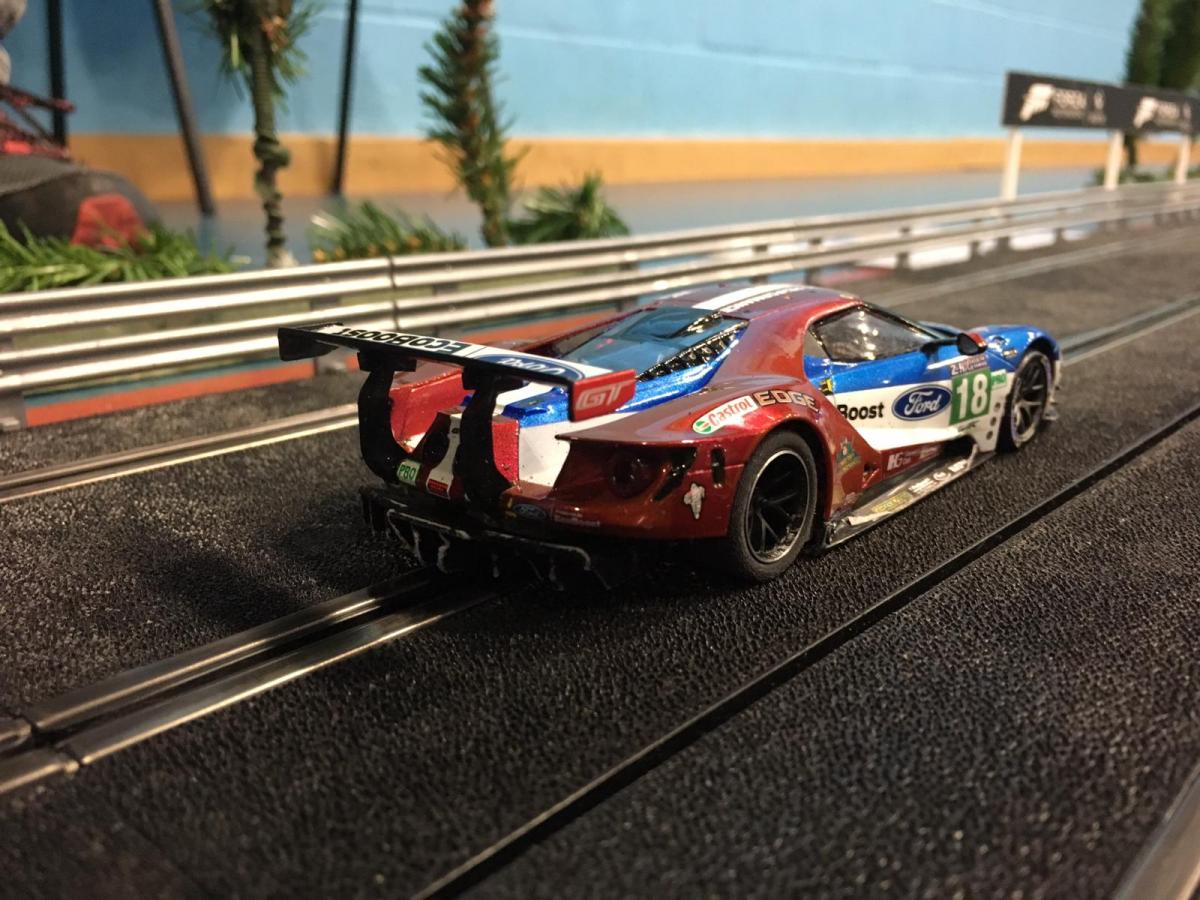

Yesterday we had an 8 hr marathon session in Best. Not that we drove for 8hrs..unfortunately no. The 3 Dutchies (Lennard, Marc & yourstruely) started

work @ 14:30 to get the

Mk2-A 2018 Ford ready for its first shakedown. 19,5 man hours later (6,5hrs x 3= 19,5 hrs in total) the 2018 liveried car ran its first laps alongside

the 2017 MK2 Ford on the Suzuka track.

And here's were all the testing, development and preparations of the past 8 week payed off. The MK2-A was stable, smooth and fast straight out of the

"box".

So we now have two set-up's to choose from: the Mk2 2017 car with a 1mm offset and the Mk2-A 2018 car with a 0,75 offset.

Does that mean that both cars are finished...No, bodies need to be reinforced. Got some minor paint touch ups to do and the SMD led lights still need

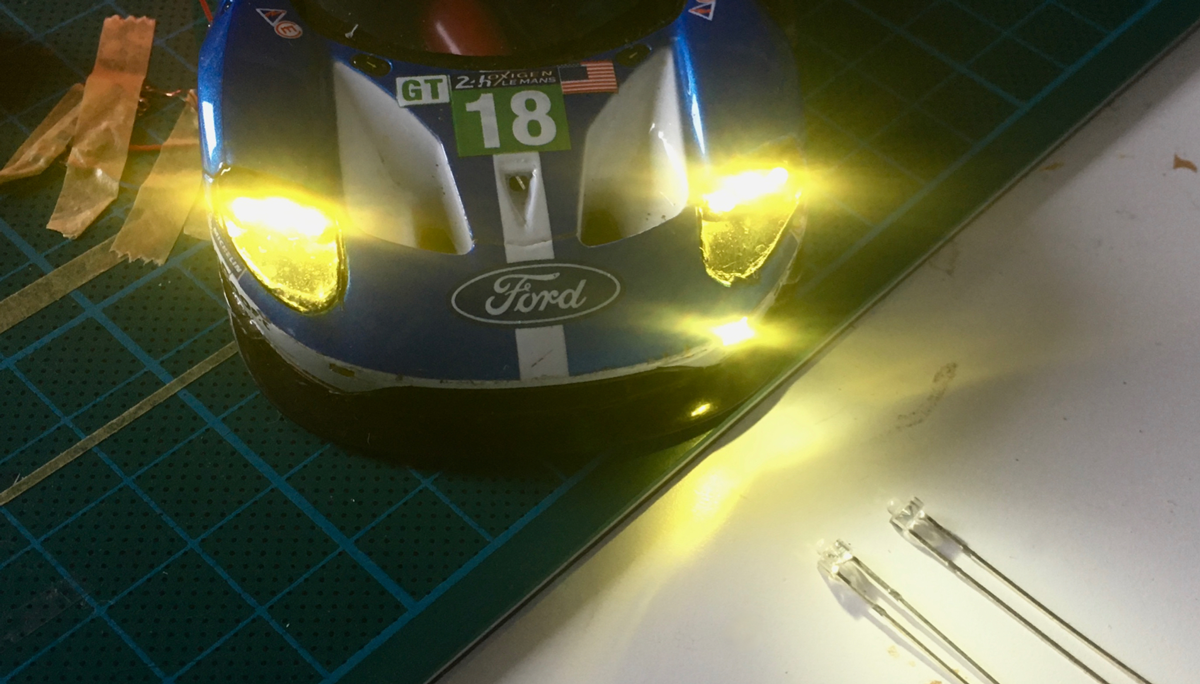

to be installed in the bodies

The latter is most likely to become a Friday morning job, and you can expect us to add the last decals on Saturday... just before concourse

But we've made serious progress yesterday, so I confident that we'll be able to hit the ground running when the track opens @ Henley on Friday

12:30

to be continued

tamar - 6-6-2021 at 11:45

After we arrived at Le Mans the race it self did not proceed as good as we were aiming for I am afraid.

I blew the light installation on the 2018 racebody Friday evening just before the start of qualifying, so that had to be redone on Saturday morning

06:00 hrs.

Then we failed post qualifying tech (rear axle too wide) which meant we ended up in Siberia rostrum wise.

We'd also been chasing a weird package drop problem which ruined most of our free practice sessions and persisted till finally solved by Maurizio

after 1 hour of running in the race.

After swapping chassis, chips, ID's, firmware and controllers, faulty cartridges on both our prime and spare controller were finally diagnosed as the

root problem.

We got a new one from Maurizio and from then on the Ford finally started to live up to its potential, but on set-up and fine tuning we were running a

day behind so we had to do that during the race.

We sorted what we could and slowly but steadily started making good progress, climbing up from dead last to 7th overall...

...but dropped back to 9th overall after a string of pitstops trying to solve what looked like a loss of power problem but in the end turned out to be

a binding front axle.

The good things were that with the front axle sorted the car ran faster than ever and Lennard posted our fastest lap time of the race with a

14.96...

...on a track that was definitely a good 2 -3 tenths slower than at the start of the race.

And that all the development bits and pieces that were on the car performed as predicted and both chassis and body survived the 24hrs nearly scratch

free.

We lost a mirror, one wiper and a sideskirt.

Last but not least, our cooperation as a mixed Anglo/ Dutch team worked really well, by working as a team we managed to solve most of the problems

that the event threw at us.

There's still plenty of development room left in the Ford..so we'll most likely run it again in the other DiSCA WEC events planned for this year.

That will hopefully sooth the pain of having to wait for 360 days before we can head up the road to Le Mans... again.

With kind regards

Tamar

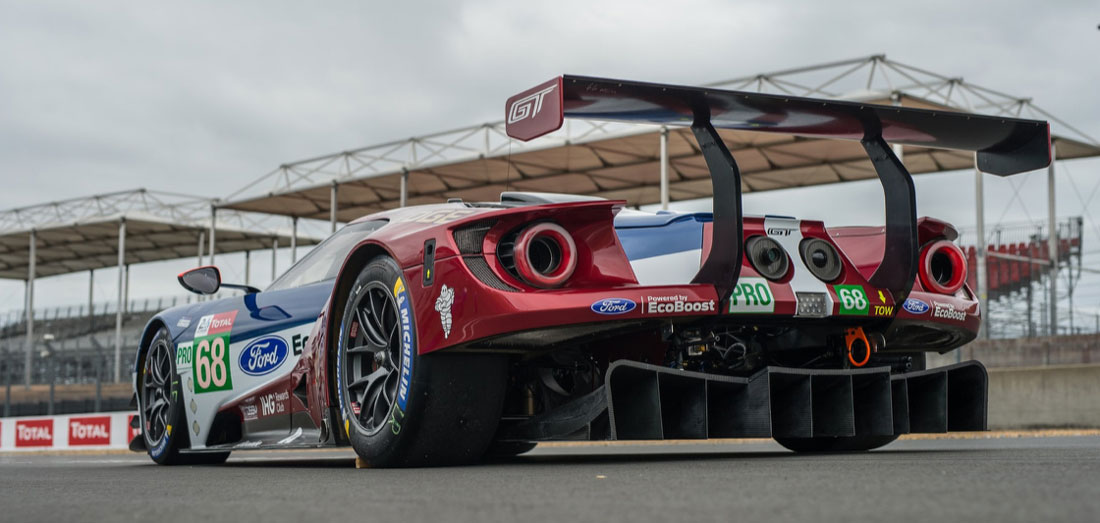

Post race pictures, the Ford finishing the race on the Mulsanne Straight.

tamar - 6-6-2021 at 11:51

Hello Guys, its been more than 4 months since my last post on the Ford GTE, in that time we've been on the Road to Rockingham and are now preparing

for the Road to Barcelona.

(well actualy Igualada but nobody has heard of that place) So...time for an update. To be honest the Ford had been negelected a bit during those

months.

After the intensity with which I had been building slot cars from January till April, I needed a break... and when I did get back into the groove,

some new projects required my attention.

So I just reread my last post LM post to see where I had left this topic and which topics I did get to post: " ...We lost a mirror, one wiper and a

sideskirt..."

Funny how one tends to remember good things and bad things immediately shift to the background. Cause in all honesty we lost a bit more than that

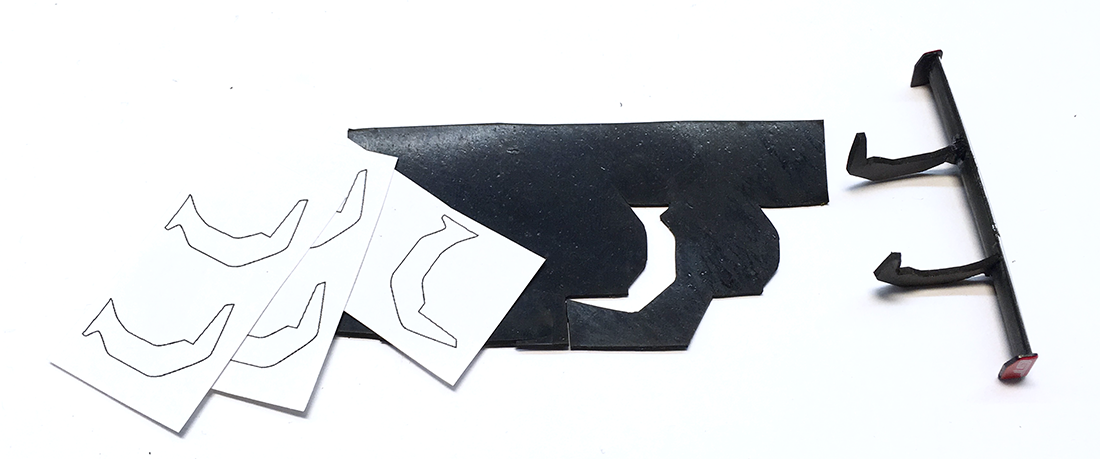

Best laid plans...

Here's one of the things I did not get to post during our road to Le Mans: Obviously the achilles heel of the Ford GTE was going to be that big rear

wing sticking out the back.

So one of the first things I did during the build was to add small blocks of foam rubber in the rear of the body to create a flexible structure to

mount the rear wing supports.

I simply cut a slit in the top of the foam so the wing supports would slide in. Over time however the wing supports started to cut through the foam

(see picture left).

So I reinforced the bottom of the foam with some thin sheet plastic (see centre pictures).

This set up worked very well during all our test runs, the foam was tight enough to keep the rear wing fin place while driving, allowed for some

flexibility during crashes...

...and should the wing come off..it was very easy to slide it back in...or replace it with one of the spares we got from Scalextric. Or so at least

that was the plan.

..and then just winging it

Well the plan did not work entirely to our satisfaction. During the first hour of practice a Marshall that wasn't paying attention to oncoming

traffic, ripped the first wing off as he lowered a car on the track...right on top of ours.

Unfortunately this would happen many more times during the weekend. Sometimes the wing would come clean off and then it was a simple remount.

Sometimes the top wing would be ripped from the supports and in a few cases the wing supports themselves would break.

Even with what I thought would be an ample supply of spare rear wings, Wayne and Stephen spend quite some time repairing wings during the 24hr event.

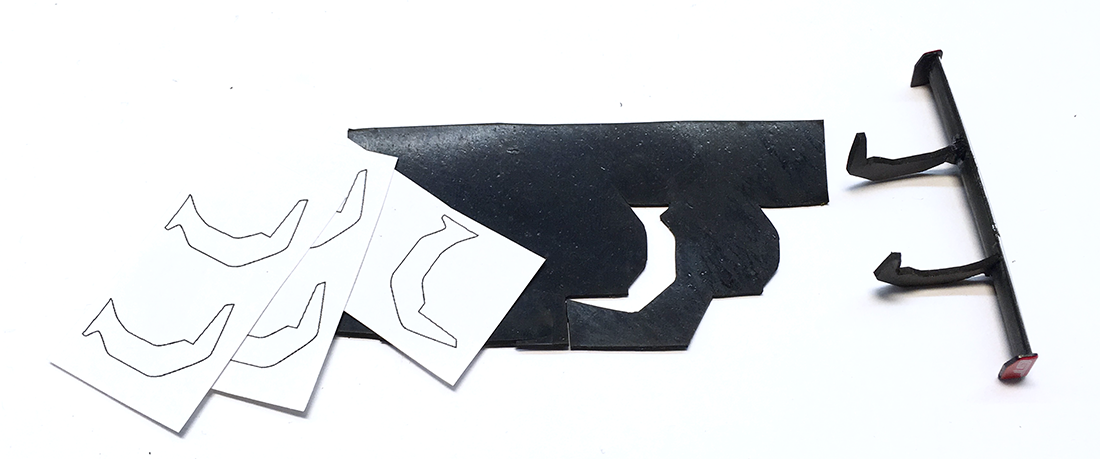

Rock Bull Rubber

So while giving the Ford some much needed TLC in preparation for the Rockingham WEC event, finding a better solution to prevent the wing being ripped

off was high on the priority list.

I gave casting the wing supports in rubber a try, but could not get the thick rubber mix to flow into the mould cavities so in the end I used the same

solution as on the GT3 Bentley.

Drawing a template of the wing supports, printed them on label sticker paper, stuck the label on some NBR 1mm thick rubber and cut the rubber with a

sharp X-acto knive.

Filed two slots in the bottom of the rear wing and used a drop of Zapp medium thick superglue to secure the supports to the wing and a small drop at

the base of the support where the enter the body.

The result, a fully flexible mounted wing. As a added security I put some shoe goo (neoprene glue) over the top connection so that even if the

superglue would fail..the more flexible shoe goo would keep the wing in place.

Worked like a dream, did the whole Saturday practice and 6hrs Sunday race with the same wing. And although the car came of several times..the wing did

not

For those that would like to modify their Scalex rear wings in a similar way. Attached to this post is a PDF with some wing support templates.

For the 1mm NBR rubber try you local industrial rubber supplier. A few quid will get you more rubber then you'll need for a lifetime.

With kind regards

Tamar

tamar - 6-6-2021 at 15:22

Some love, some hate them. Main reason racers use them is to reduce weight high up in the body, although I'd say the added flexibility they

give the body is just as important. And with Ford not having that much "high" in the body, for this car the most important reason.

So its a performance part..but that does not mean you can't make them look good.

I.m.o a badly executed set of vacformed windows can totally ruin the look of a car. Unfortunately not an uncommon sight on "performance slotcars.

Clear windows, no window frame, no window streamer, the Dutch have a nice word for it "Blote billen gezicht" Google it, you'll have a

laugh.

Ok let us dail back the clock to somewhere mid March when Marc brought his Vacform machine to the club and used the bucks I'd perpared to pull a

couple of windows and headlight lenses.

The copies were perfectly clear and had good shape definition, but...when we cut some of them and did a test fit...

...the big one piece front and rear window was too big, it would not fit inside the body.

I knew this was going to happen, because the buck I'd cast was an exact copy of the Original Scalex window.

For Vacforming the most used material is 0,2 mm thick PET sheet. During the vacforming process the sheet is drawn over the buck.

As a result of the material thickness the size of your Vacformed copy will be bigger than the original.

There are ways to make exact sized vacformed copies... but there was just no time to make a second positive silicone cast and pour a negative buck.

In this case it wasn't such a problem as all I had to do to make the windows fit was to cut the front and rear window loose and mount them seperately

in the body.

There was still a small gap at the rear of the side windows, but at the time I could live with that.

...how to trim and detail them...

The hardest thing with cutting clear parts is to see where exactly you need to cut (even with my reading glasses) because they are..clear parts.

Depending on the quality of the vacformed part finding the edges can be difficult.

So here's a tip: use a fine steadler (waterproof) feltpen, and outline the parts before you cut them. Here's how you do that.

Flip the vacformed part so the inside is facing up. Stick the tip of the pen in one of the corners push the tip to the outside wall and gently trace

the outline.

Don't worry if you make a mistake or your pen slips, it happens, even to me. Just wait a bit for the marker ink to dry and use a toothpick to

(carefully) scratch away any excess ink.

vacform_tracing-outline.jpg

Tracing the oulines before you cut the clear parts makes life a lot easier as you'll have a better guide where to cut.

To make the cut I use a pair of small curved and straight scissors to cut out the rough shape. Then its a repetition of test fitting and trimming the

part to get that perfect fit.

For the fine trimming of the edges I don't use the scissors but a small sanding block/stick. Allows for much fine adjustments and gives a nice and

smooth edge.

The window frames on the side and rear window were lined on the inside with the same fine steadler felt pen.

Remember how I mentioned in that earlier post how the silicone would copy anything, even the tiniest surface details like lettering on the window

streamer or the tiny raised window frames?

Well these sure helped here as I could use the small edges as a guide to ink the window frames.

So a thin marker for the outlines and then I used a broader pen to fill in the whole inside. You might have to do several passes with the marker for

larger areas like the air intake.

Cherry on the cake were the decals I made for the window streamer .

.

.

..and how to mount them

So now you have you vacformed clear parts trimmed, detailed and ready to mount. As I mentioned before adding more flexibility to the slot body was the

main reason to do them.

So for that reason I prefer to not to glue them rock solid with glue, but mount them with as much flexibility as possible. In most cases that means

(double sided) tape.

For most GT's the tape will be covered by the window frame(s). In general I add full width tape to the top of the windows and just small tabs to the

sides and bottom.

When its time to firmly secure the clear parts for a race I usually add a bit of UHU Schnellfest to the corners.

It is a two component glue that remains a bit flexible and dries totally clear.

From what I've heard its similar to the GS Hypo glue some UK members like to use.

But sometimes your clear parts have very thin window frames or like the headlight lenses, none at all. Here's where I use a black 1,0 mm wide and 0,2

mm thick doubble sided tape from 3M.

Altough tape isn't the right word, its more like mini window kit on a roll. Not surprisingly as its main use is to glue LCD screens to smartphones.

Simply mount the tape to the edges of the headlights and press it firmly in place with the backside of a brush or a toothpick.

Once you've removed the backing paper all that is left is a thin black edge that resembles scale window kit. Then press the part in place on top of

the tape.

It is the only black colored tape that is strong yet flexible enough to mount clear parts on a slotcar body. As it vulcanizes the longer it stays on

the stronger the bond gets. And it looks amazing.

Here is a link to a Dutch Webshop that sells the tape, but you should also be able to source it from your local mobile phone repair shop.

Ok that's it for now, one more backlogged post sorted...more to follow

With kind regards

Tamar

tamar - 6-6-2021 at 15:42

Almost done with my backlog posts on the Ford GT LM, I must say, looking back to this topic, wow I really went all the way with this little

racecar.

And as in live, the road travelled was almost more rewarding and interesting than arriving at our destination.

Because what was initially a simple Plan B to get us to Le Mans, quickly grew into something much more complicated.

The challenges this little Ford raised have tought me a lot, the lessons learned already being applied in new projects.

But now after 6,5 months, 8 pages full of post, almost 10.000 views, it is time round things up and bring this project to a close.

I must say, posting and building at the same time did cause this thread to swerve off topic from time to time and had me skipping from one topic to

another.

So this one...with a bit off hindsight, can be considered as the Ford GT LM epilogue.

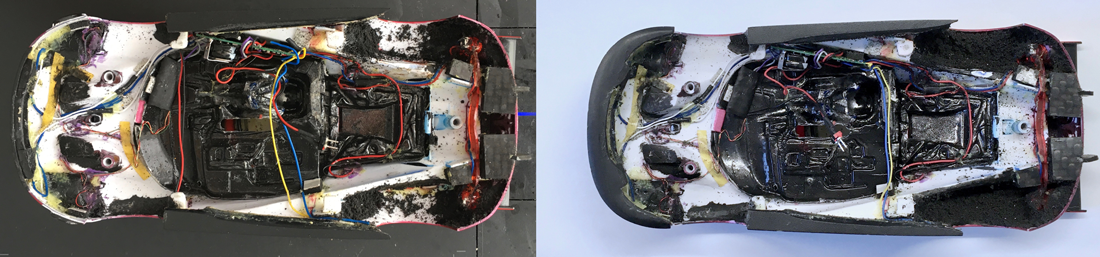

Ford GT LM...body double

For our trip to Le Mans two complete Ford's were build, one would serve as a test mule and was destined to do most of the free practice running the

other would be kept clean and fresh for the 24hrs race.

We ran one car in the 2017 livery and one in the "special edition" 2018 livery courtesy of Hornby Hobbies. So wha t was so special about the 2018

car?

Well, when I talked to Simon about our plans to do the 2018 car...if we had the time. He mentioned that he might have one for us laying around.

Its was a dis-approved pre-production sample with a minor discoloration error. I could have it under one condition: That I would not sell it after the

race!

(apparently like a misprint on a stamp this tends to make such an item rather unique and increase its value somewhat)

Well Simon, rest assured, this little Ford will never leave my possession, as a matter of fact I might pick up a second 2018 car when they will be

released 4th quarter 2019.

Because the metallic color of the car is just stunning.

As you can see on the picture right. I did some paint tests as I needed to touch up the paintwork on some of the areas where I'd modified the body

work.

In the end I decanted some Tamiya TS 39 & TS 95, mixed 1:1 and applied it with an airbrush.

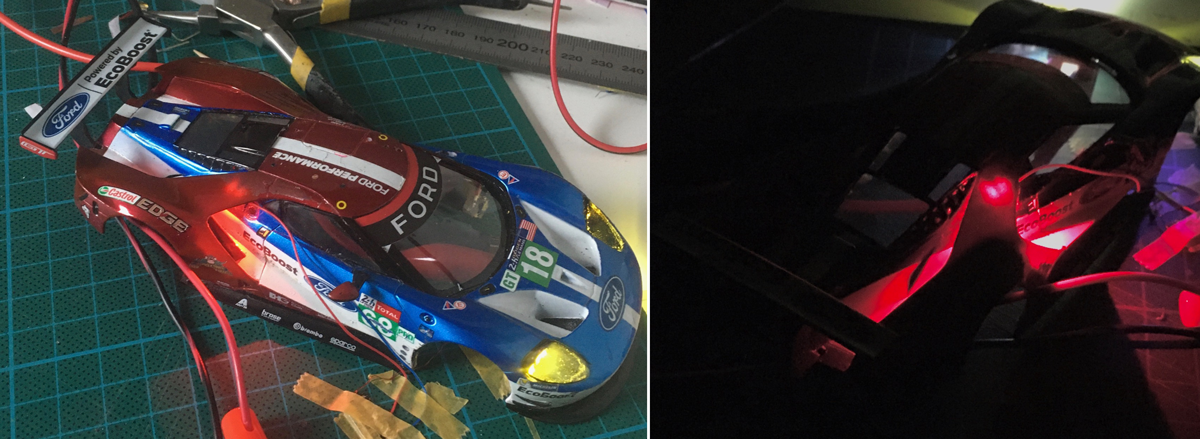

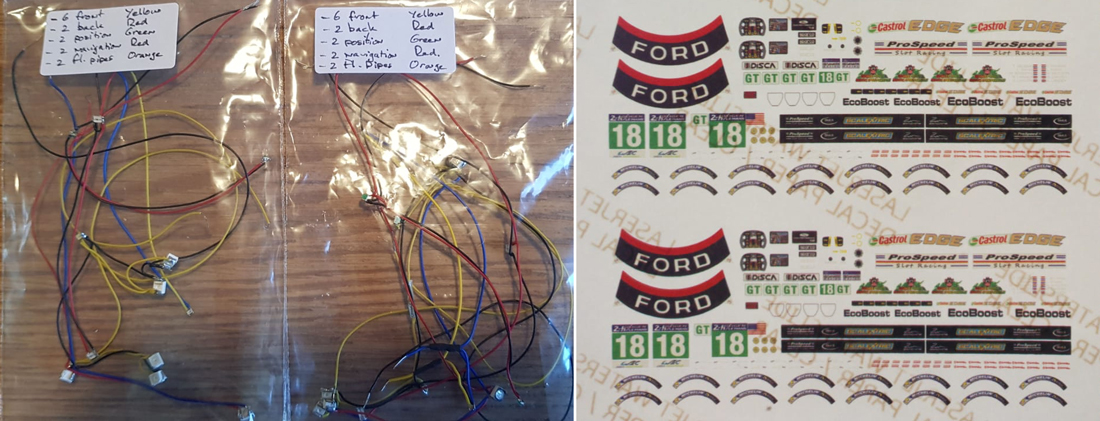

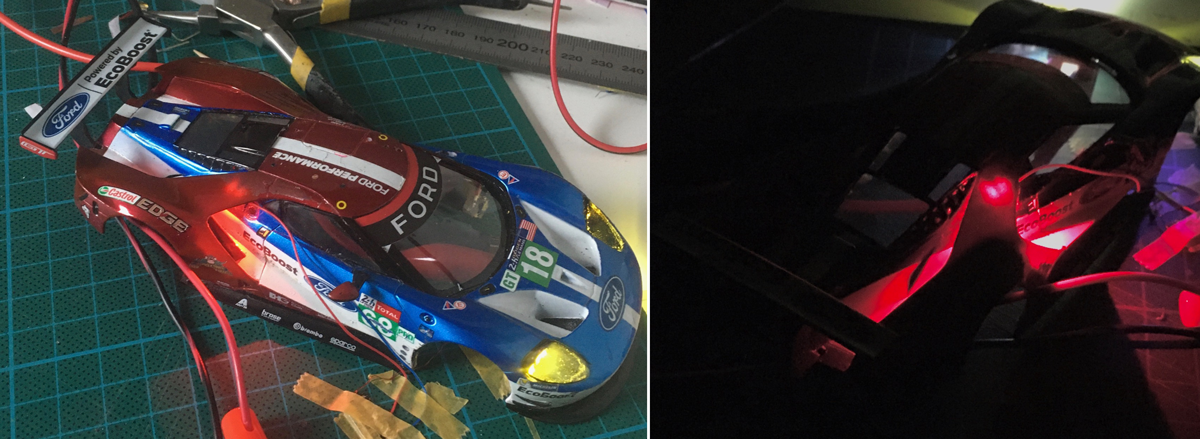

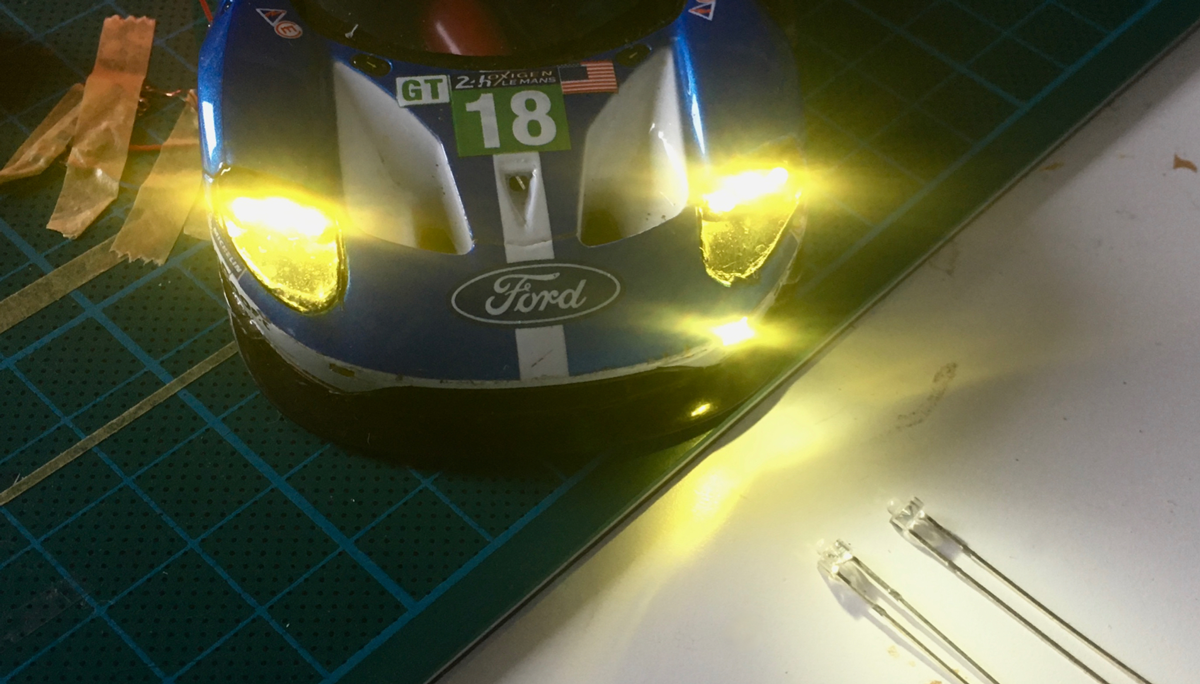

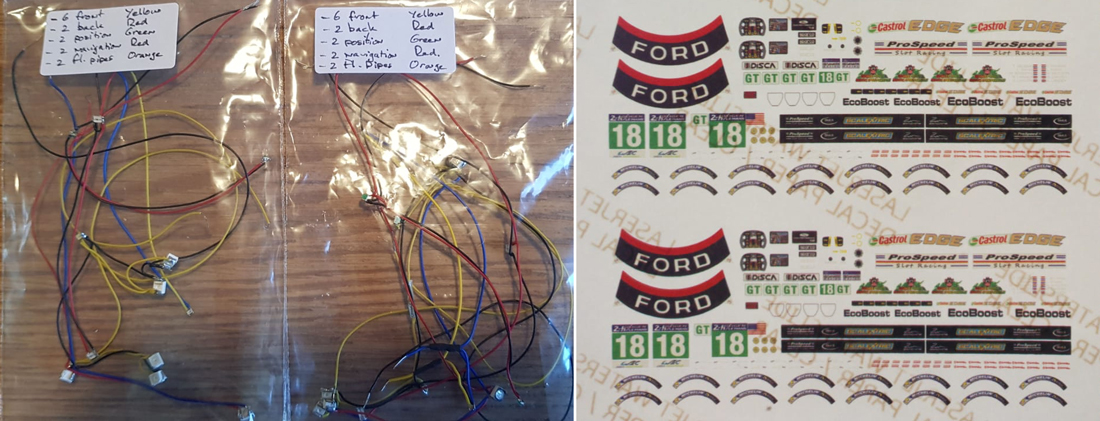

Lights: Short circuit and short cuts

One of the things I never got to post prior to the race, the lights. Main reason of course was that we still needed to mount them as we left for the

UK on Friday.

Me shorting out the light chip on Friday evening just before the first qualifying session didn't help. Luckily we had the body double which, with a

very rudimentary light set,

allowed Wayne and Stephen to do some night running. Z-machine had send us an ample supply of spare light sets, so the alarmclock was set for 05:30 on

race day, first job

was to start repairing the lights of the race body.

Funny how time flies when you most need it, in order to get the car finished in time for the start of Saturday morning 2nd Qualification session we

would need to make some (short) cuts.

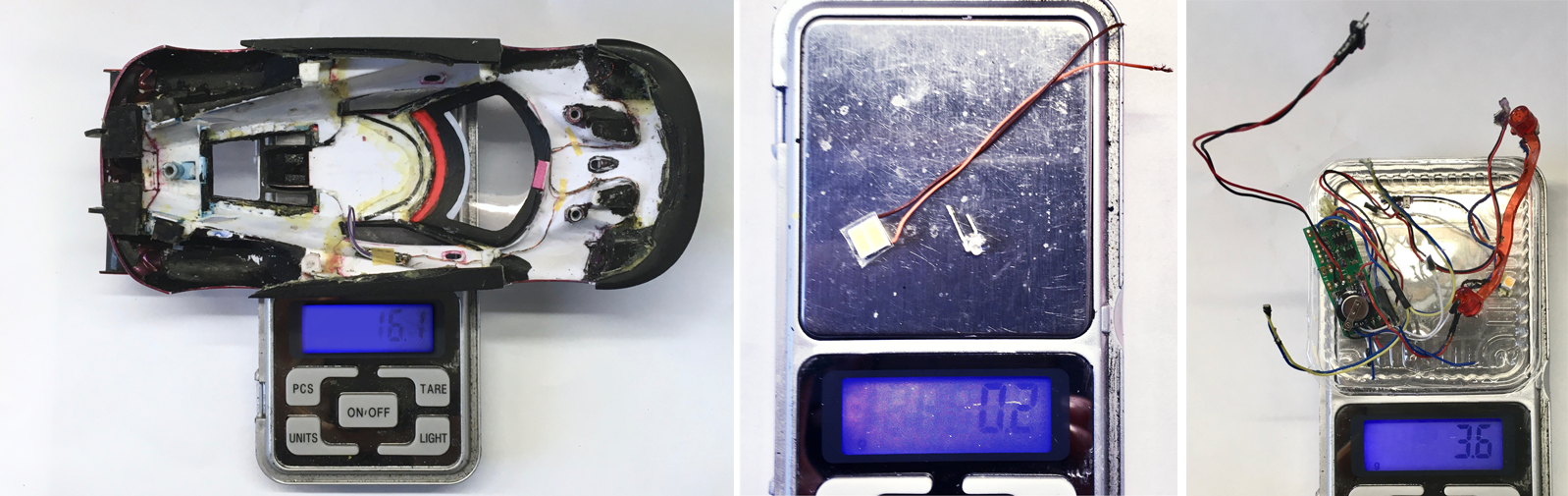

With the Ford sporting 8 leds at the front and no time to properly trim the wiring, using the stock wires would add another 1,5 - 2 gr to the body.

But as I went through my spare box I found a spare light set Fola had made for the Toyota TS040 we raced in 2015.

The headlights of the Toyota had 3 tiny round smd leds and one square on each side and they were mounted on very thin laquered armature wire.....and

guest what...

..not only were they a perfect fit for the Ford's headlights, they were also much lighter.

Lights: Friend or Foe

Where on a race car the lights are there for the racer to be able to see the track, on a slot car the lights are there for the racer to be able to

see...his car.

And believe me on a digital track as big as the 1/32nd La Sarthe...that can be a harder job than you may think. Running in a pack going into the esses

or rounding Mulsanne corner...

...every bit of extra light that will help you to identify which car in that cluster of lights belongs to you...really makes a difference.

With the distinctive triple headlights and two fog lights, we had the front covered. The sides...hmmmm not so, ok those extra identification lights

behind the cockpit...

...we did not want them to be as bright as the neon light Ditslot had done the previous year. But due to the short cuts we had to make repairing, all

the side lights were a bit dim.

We also ran with the flaming exhaust led on the right side as this was the visible side and helped you spot your brake point on the Mulsanne

Straight.

where the car lacked identification most was at the rear. Sure the Ford's taillights were pretty big, but they shone just as bright as all other

cars.

An extra identification light at the rear would have helped here...something on the wishlist for next year... as are the glowing brake discs.

More diffuser follies...

Here are some more diffuser follies I dug up from my image folder. I'd almost forgotten about this one, and that while it was one of few occasions

where I've been able to add scale detail...

...and improve the performance of a car in one go. So what are you looking at? Well, after our first test runs with the diffuser attached to the motor

pod one of the team members wondered:

Wouldn't the added mass behind the real axle be ditrimental to the un sprung weight and performance of the car?

My initial reply was that on all the SW- short can cars we'd raced so far, the best set up had a bit of weight under the rear axle....but ok...

let's see if we can make the diffuser lighter.

So I cut off the 0,7mm thick diffuser strakes and replaced them with very thin plastic cut from a booklet cover.

And behold even though it was but a 0,6 gr weight gain on a 2,5 gr diffuser..it did make a small difference...the cars was 0,05 sec faster... and it

definitely looked much better...

..and as the strakes were now flexible...it improved the crash resistance as well. Absolutely loved it...but the time...and effort. You can understand

why I modified only one diffuser like this.

Ford GT LM Set-up : Control and adjustability of chassis, pod and body movement.

Ok, enough talk about detail stuff, time to get down to the nuts and bolts of the car. Here's some more info on the technical side and the choices we

made on the Ford's set-up.

Some slotracers look at a car and see the chassis as the part that makes the car go, and the body...well it needs to have a body right? But its mainly

considered as dead weight.

So let's get rid of that dead weight as much as possible...right? True a lot of time and effort has been made on the Ford bodies to make them light,

not as light as possible but very close to the minimum.

But even if you do get down to the DiSCA min. 19,5 gram, that's not dead weight sitting idle on top of your chassis. That's weight you can use to

make the chassis work...even better.

Take most 1/32nd slot cars out of their box and you''ll have a car were chassis, pod and body are screwed tightly together as one. As such any

movement of the car will be transferred to all parts.

If the car leans in a corner it will do so as a whole, if the car rides a bump in the track it will do so as a whole. etc etc. On a plastic track,

specifically a Ninco track..that's no good.

In an optimum situation you would want all parts to be able to move independently and at the same time be able to control their movements and

interaction independently.

Alas in most cases you'll have to settle for a compromise.

So first thing most will do is give the car some body and pod float, dump the horrible wood screws that will scrape inside the screw holders for a

good set of half shaft metric ones...

...and your 3 components (body chassis & pod) can move independently. Loosen the body screws a few turns and you'll be able to control the amount of

float, at least..upwards.

Where the body will rest on the chassis is often a different matter. Plastic tends to warp and bend as it gets loaded, some start to do so from the

factory.

A lot of slot cars are designed in such a way that the body will rest on the chassis side skirts and front splitter. As such they will transfer the

body weight to the chassis everywhere...

..and in most cases...no where in particular.

Body Supports

I prefer to have the body transfer its weight to the chassis on 4 points only. To have those points spread as wide apart between the axles and as

close to the axles as possible.

So if on the stock car the body rests on the side skirts (as with the Ford) I will cut those off and glue them to the body. As such new body supports

will have to be fabricated.

These are easy to make, just cut some pieces of think plastic rod or L shape, glue them in the body and cut them to the right size. Which is basically

what I did Ford the first Ford prototype chassis.

Later versions had a more controllable set-up with a holder for a grub screw incorporated on the chassis. The picture below shows how I glued the 3DP

body supports into the body:

Tacked in place with some thick superglue and covered with neoprene glue to secure it in place, should the flex of body, during a crash break the

rigid bond of the superglue.

My base set-up for almost all my cars is always to adjust the grubscrews so that the body rest squarely on 4 points evenly.

C.o.G or Centre of Gravity

As a rule of thumb, you'll want it as low as possible. So remove material at the top of the body where possible, vacformed windows etc etc. all that

stuff has been covered in my previous post.

Before we switched to the Ford as a plan B, I'd been working on the BMW M6, just one look at them side by side and you can easily tell which of the

two had a lower C.o.G.

The lower you're C.o.G the less prone the car will be to tip over on corner entry. And with the lightweight parts and body supports the Ford was rock

solid in that area, better and more stable than the M6.

So you could carry more speed into the corner. But when we ran the two side by side, mid corner and on the corner exit it felt like the M6 had more

grip.

Inertia & weight transfer

Now at this stage in testing the Ford needed balast in the body to get it on the 19,5 gr min weight, which we had placed low in the body. So it looked

like we'd lowered the C.o.G too much?

Indeed we had, because when we moved some of the balast higher up in the body mid corner grip improved immediately, corner exit remained the same

though.

When I checked the body after some test runs I also noticed we had more tyre deposit in the body than on the M6 and that the tyre wear on the Ford was

higher.

We had to much wheel spin coming off the corner. So here's the last bit of set-up trickery we used to get more traction coming out of the corner.

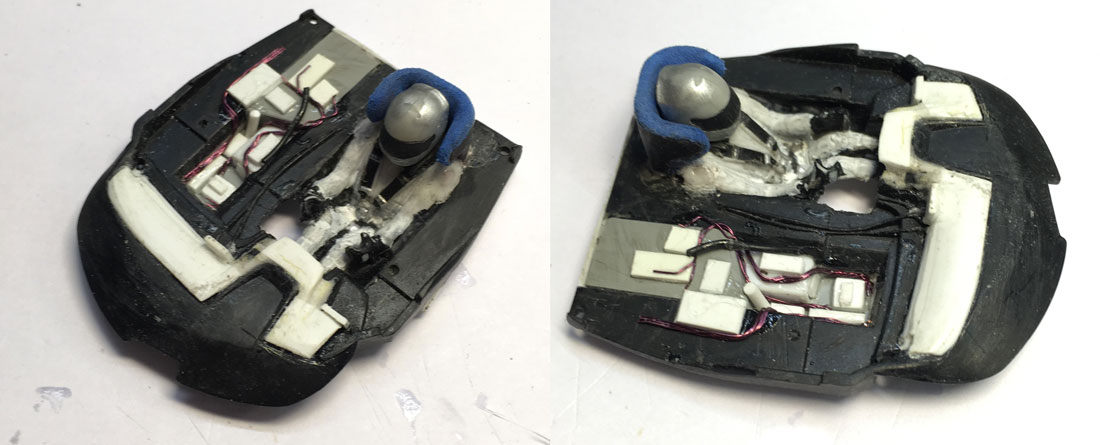

We had cut the diffuser from the chassis and mounted it on the pod to solve the ground clearance issues.

We were running the Ford with a bit fair amount of body float to allow it to rock and use the weight transfer to load the chassis.

But as there was now no more "chassis" behind the rear body supports, there was also no contact point behind the body supports to transfer weight to

the rear axle.

Then I remembered how Nick de Wachter had used a big block of soft sponge mounted on the back of his Dome chassis to generate more grip.

During acceleration the body would tilt backwards and make soft contact with the sponge and via the sponge would transfer weight onto the rear of his

chassis.

So I took a piece of foam rubber glued it on the diffuser where it would just clear the of the rear of the body.... and whoa, I now had much more grip

coming of the corner.

(if you look close you'll be able to spot the first foam test set-up in the centre image at the bottom of this post )

So the principle worked, all we needed now was a way to control and adjust the moment of transition.

As luck had it Stefan Nalbach had incorporated two body supports on the diffuser of his original chassis design. So all I had to do was glue two

pieces of foam in the body directly above the supports.

I covered the foam with some sheet plastic to keep the grub screws from biting into the foam...et voila, we could now adjust the amount and timing fo

the weight transfer under acceleration.

Ford GT LM Set-up: Lessons learned the hard way

So here's the final bit on set-up, prior to Le Mans all our testing had been done on the permanent Suzuka track, which is a challenging track with

chicanes, slow, medium and fast corners and a pretty decent straight.

To accustom ourselves to the longer gear ratios we run at Le Mans we used those in testing instead of the shorter ratios better suited for the Suzuka

track.

From experience we knew that if a car set up like this ran well @ Suzuka it would also run well at Le Mans.

During our testing we had run both SW chassis with different off set pods. Testing the slot.it 1,0 mm offset and 0,75 mm off set back to back. They

were both fast, but the 0,75 was just a bit easier to drive.

It had more flow, it would roll easier into the corners. The 1,0 offset had better brakes, more aggressive acceleration but also needed more work to

keep it flowing through the Esses.

Lennard and Nick (Helmich) were faster with the 1,0 offset, Marc and I were faster and more important more consistent with our laptimes with the 0,75.

With Wayne and Stephen not being able to test run the car until we were in Henley, I was convinced the 0,75 pod would be our best option.

Well...I was wrong!!

This is written of course with the benefit of hindsight...and after having raced the Ford GT LM at Le Mans... and the Rock Bull ring, two very

different tracks compared to Suzuka.

Not being able to concentrate on back to back testing of both offsets at Le Mans (caused by our controller problem) did not help, nor did the added

stress of having to finish the lights on the race body etc etc.

But in all honesty, I just was not sharp, I wasn't on the ball, even though the signs were there. They say even a donkey does not fall in the same

hole twice... but I did.

The previous year Ditslot I3D had run their Ford with a 1mm offset, and even though Stefan (Kievit) and Lennard had been faster with our Corvette

(running a 0,75 mm offset) Ditslot had been more consistent.

This year even after we finally got the Ford sorted and were running well, we were being outpaced on consistency by the Posillipo Ferrari... and the

Prospeed Corvette. Both running bigger offsets than us.

Now I had no reference times for the Posillipo car, but Prospeed had tested their Corvette with us at Suzuka and even if you were to take in account

the home track advantage...

...the Ford had been quite a bit faster. blink.png

After Le Mans I did the usual post race inspection, found the chassis to be in perfect running order. During the race we did notice that we had much

more wear on the right braid than on the left.

We had the issue on Sunday morning with the right front wheel binding and discovered that it had also worn down so much that the plastic rim was

visible.

And even on the spare axle we fitted ( the chassis picture above was taken during the postface inspection) wear on the right was much more than on the

left.

It wasn't until I took a real close look at the body (with just the windscreen wiper, a mirror and its left skirt missing) that I noticed that the

right rear body support tab had come loose.

Loose as in being able to move up and down a bit, with just the neoprene glue keeping it fixed to the body.

Apparently the Ford had been hit hard on the left side, most likely at Mulsanne corner which took off the skirt (because that's were after the race I

had found it).

This crash most likely worked loose the right rear body support. As a result the weight was transferred unevenly on the chassis. Uneven weight, uneven

wear..but we made it to the finish.

After Le Mans my slot race focus shifted to the Oreca LMP1 prototype that we hoped to get ready for the e-csd 24hrs end of June, and when that was

cancelled, shifted to the development of the LMP2 version ready for Rockingham.

During that time I took the Ford for a couple of test laps and immediately noticed that it had no brakes and no torque, even after changing to a

gearing more suitable for Suzuka.

I put the car on the magnet Marshall and compared the values to what they had been pre Le Mans, yup, the motor magnets had been cooked by the long

15x28 gear ratio.

Down Donkey, down

Time flew by and all of a sudden Rockingham was right on our doorstep, time to give the Ford a major once over. We'd raced at the Rock Bull ring last

November, nice track.

Relatively flat (at least for a temporary track), medium length straights. One long straight with a tricky braking area with an LC smack in the middle

of the brake zone.

Three sets of hand out tires for just 6hrs of racing. With the lessons learned from Le Mans I had no intention of being a donkey again.

So I decided to set-up the chassis with the 1,0mm offset and a way shorter gear ratio, but no time for a quick test session @ Suzuka.

Upon arrival at Rockingham the Ford ran well pretty much traight out of the box, even with the 1,0 offset it was easy to drive and had a nice flow

through the corners.

Stable and consistent more or less what we had experienced with the 0,75 pod @ Suzuka. question.gif

Still needed a bit more brake so dropped a tooth on the pinion. On pace the Ford was just as fast as the leading LM P2's and even matched the speed

of most of the LM P1's.

Even our newest Danish team member John Anderson managed to put in some pretty decent lap times after he had become accustomed to a new track, a new

car and a new very demanding team captain.

We had to pit just two times for repairs, once after I'd hid a desolated car under the bridge at full speed: soldering on one of the light kit lead

wires had broken.

And once as a precautionary repair as I'd noticed one of the side skirts had come loose after an other crash. This time I was on the ball.

Back home the post race inspection showed both body and chassis to be in good health no damage, even wear left right on the braids, the front and rear

wheels.

We had used one set of N18 during the first 4 hrs with just 0,6 mm wear (0,15mm p/hr). Switched to the F22 for the last two hours and ran those down

to 19,6mm, (0,5mm p/hr) yikes.gif

Horses for courses

Two weeks ago I ran the Ford @ Suzuka again..and guess what... with the 1,0mm offset and same set-up, way to much brake, way to much and aggressive

acceleration and hard to get a nice flow through the corners.

And then it dawned on me, even though a car set up for Suzuka would run well on Le Mans and the Rock Bull ring there were similar differences between

them and Suzuka.

1 Le Mans and the Rock bull ring are temporary tracks, and have less tyre deposit & thus less grip than the permanent Suzuka track.

2 The corners of the Le Mans and Rockbull tracks are flat or at least not banked in the way most corners are at Suzuka.

3 Besides banked corners the Suzuka track also has more undulations where the track rises and falls as it follows the terrain. As such it requires a

bit more ground clearance.

The result of these 3 combined mean that @ Suzuka you need to run a smaller offset on your pod and with the higher grip levels can get away with a

lower gear ratio.

So gents, mental note for Le Mans 2020 and all those who plan to take part in the Suzuka 6hrs...horses for courses gents, horses for courses wink.png

When the flag drops...the bullshit stops?

Time for some closing words on our 1/32nd Ford GT LM, its road to Le Mans...and then a bit more. Future projects are calling, a renewal of plan A.

But if there's one thing prepping testing and racing the Ford over the past six months has learned us... its always good to have a plan B.

For Ford running their LM GT had always been a 4 year project, winning Le Mans on its first outing and then Daytona, they had nothing left to

prove.

Being caught out on the wrong side of the B.o.P several times didn't motivate them to extend the program nor do they seem to be interested in moving

on to a Hyper car.

Their plan B of extending the life and success of the GT LM in the GT AM class was met with some peculiar and very strict regulatory measures by the

ACO.

They say when the flag drops...the bullshit stops, while that may still be true if you cross the finish line winning (your class) in 1/32, but at Le

Mans.... unsure.png

With kind regards

Tamar

P.s: A big thank you to all who have helped me with this project, special thanks to Simon Owen from Hornby for going the extra mile, providing us with

spare cars..amongst one very special one.

Philippe Laudet for his outstanding Z-machine light kits. Slotfabrik for the decals and C&C designs for the decal plan B.

And last but not least, a very warm thank you to Stefan Nalbach for the endless hours of work, redesigning the 3DP ProSpeed chassis every time I would

come up with yet an other modification.

tamar - 6-6-2021 at 16:05

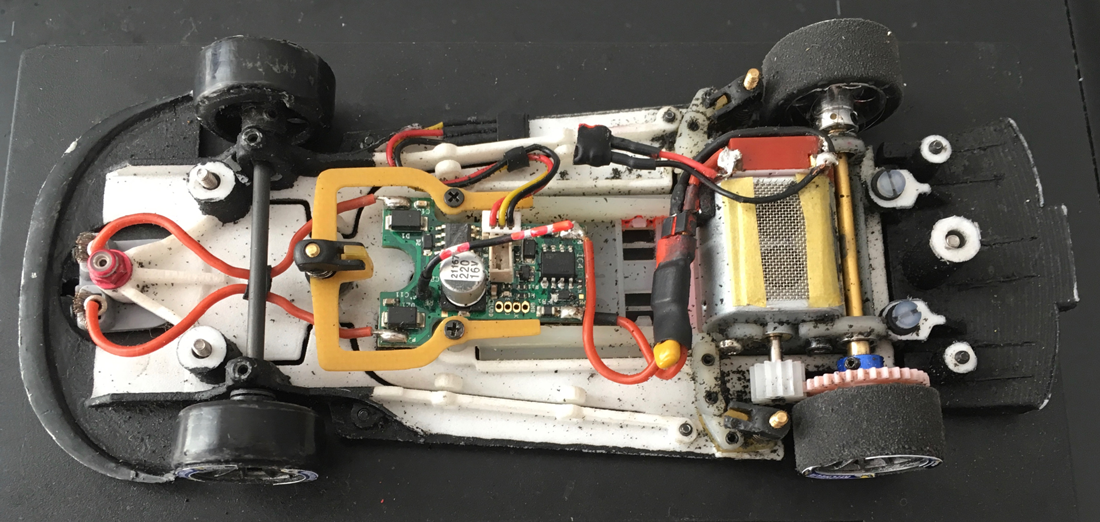

When my part in the Organisation of the DiSCA Finals @ Igualada become more time consuming than provisioned, Plan B, a.k.a the by now

trustworthy #18 Ford GT LM had to be called upon once again.

As the Ford had been one of the test mules for the Policar evaluation we did on the Slotracing2go track so I had a base set-up to start with, but that

test run also reminded me that there still remained some

unfinished items on my to do list.

To do list: Rework Lights wiring

Clean up and rework the lights wiring was one of them. May look like small detail stuff, but bad wiring can actually seriously fuck-up your car's

handling.

And its almost always something that you notice post race and makes you think "will do that for the next one". And then you forget about it until

its too late, and off course and you have to run with it again.

So...not this time mate.

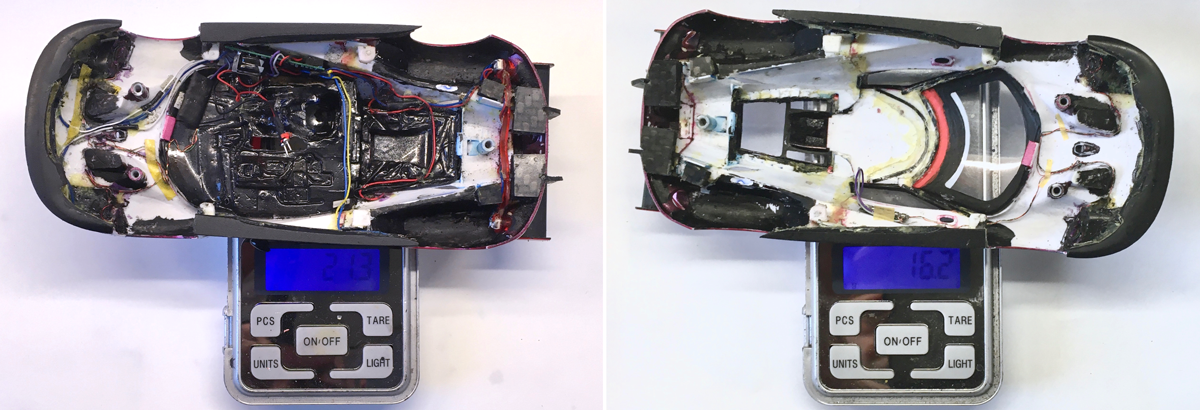

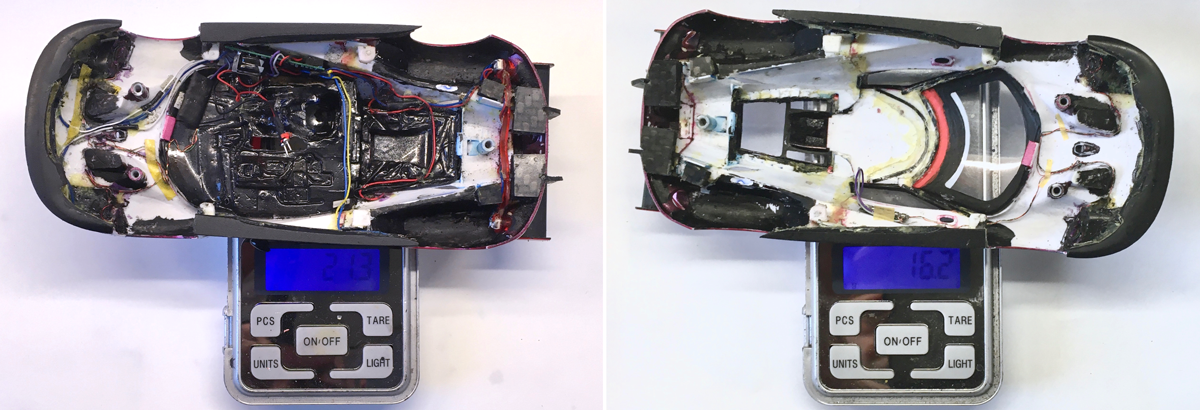

On the left, lights wiring after Rockingham, on the right after Igualada, also noticeable here the front splitter now attached to the body

On the Ford we had two sets of wires crossing over from left side of the body to the right. The red & blue were for the green position lights, the

yellow and blue were for the Flaming exhaust led's.

During the hectic 05:30 hrs Saturday morning fit the lights before the lM 24hr race session..both had been cut a bit too short.

Not by much, but I later discovered that they did interfere with the body float. As the Finals would not have a night session I carefully removed the

position lights and wire from the body.

Did not want to miss my flaming exhaust pipes (great indicators of you brake points when you car runs parallel to your driving position) so I rerouted

those.

I also remounted the Z-Machine light chip on fresh pads a bit higher in the body. Turned out that the Capacitor kept the body from resting square and

flat on the body supports.

Last but not least. I used more flexible wires for the connector to the chassis. The stock ones on the Z-machine chip can be a bit stiff, stiff enough

to lift the 20gr body from the supports.

With the chip remounted and cleaned up (softer) wires the body now rested rock solid on the 4 support mounts.

To do list: Remove Front Splitter from Chassis.

This modification had intentionally been left on the to do list. In general I prefer to run my cars with the front splitter attached to the body and

not on the chassis as with most RTR cars.

But as Stefan Nalbach had copied the Scalex chassis in its initial ProSpeed design, we ran the Ford @ Le Mans in this configuration..what can I

say...it makes one hell of a great bumper.

As John Ny would join the team and make his debut in DiSCA racing @ the Rockingham 6hrs, I though it might be best to keep that bumper for one more

race.

John proved himself as a very stable driver and didn't put a scratch on the car so when it became celar that we would run the Ford again in Spain..it

was time for the splitter modification.

The reasoning behind this modification is that I want to be able to set, adjust and control, body & chassis movement independently.

On the Ford that big splitter works great as a bumper, but it also works as a snowplow, grabbing every unevenness on the track.

It would also lift the front of the body every time the guide encounters a bump on the track.

So off came the 3dp splitter from the chassis, and onto the body I crafted the Splitter I had cut from the OEM Scalex chassis. (also see top picture

right with the bodies on the scale)

Works better and looks much nicer. As usual my preferred method to attach the splitter to the body was BisonTix Neoprene glue. Tough as hell but it

always remains a bit flexible,

just enough to be able to give a bit in a big crash. Picture above right was taken after the Igualada race, the splitter did take a few hits...but

didn't move an inch, not even a 1/32 inch.

DiSCA WEC Finals, Catalunya 6hrs: I just love it when a Plan ( B ) comes together.

With all the mods and detail jobs done the Ford was ready for its first run on the lovely Catalunya Policar track. Nice track, nice lay-out with some

wide open corners some of which were taken almost flat out.

But surprisingly during the practice sessions the Ford struggled a bit for grip, mostly on the 2nd half of the circuit. It was still one of the

fastest GT's, but we had much less grip than usual compared to the Flat-6 engined LMP1's.

With hindsight and for reasons I have explained in more detail in

[url="https://www.slotforum.com/threads/disca-wec-gt3-european-final-igualada.190749/page-3#post-2284725"]this post[/url}, we lacked a bit of

magnetic downforce.

The smooth and flat Policar track gave us a higher ground clearance as the distance between the motor and the track rails was bigger than on Ninco.

Top picture the Ford GTLM on fresh 20,6mmø trees, Bottom picture with the rund down 19,2mmø N18's after 6hrs of hard racing...but still with

ample GC under the diffuser.

After running for 2,5 hours on the same N18's did the Ford finally started to behave. With the SW MX16 configuration the lower the tyres got, the

better the car handled.

So when I handed the car over after 3 hrs Marc (Wiggers) asked should'nt we change tyres? A quick check for GC showed we had more than enough, so we

ran the whole 6 hrs on the same set of N18's.

In fact he smooth and flat surface of the Policar track allowed us to run the tyres down from 20,6mmø to 19,2 mmø with still ample GC at the end of

the race.

I tested the magnetism of Ford GT pre and post race and it went from 1773 ut at a GC of 1,7 mm on a tech block, to a whopping 2330 ut with a 1mm

GC.

Off course the only reason we were able to do so was because our Diffuser Mod to mount it on to the motorpod.

Had it been attached to the main chassis we would have been dragging our ass on the track after 3 hrs.

As Hannibal used to say I. the A team:" I just love it when a plan comes together."

With kind regards

Tamar

tamar - 6-6-2021 at 16:19

Less than 3 weeks till the DiSCA Le Mans 24hrs, sounds familiar? Well yes....it does.

Just when she though she might be able to enjoy her retirement, no more being plan B. Just one more Mission8 test to go serving as a reference car

...

...and all of a sudden she's booked for a whole new season. The main star in "The Road to Le Mans, the Sequel", winning its class at the Suzuka

6hrs as a warm up.

So if you want to follow the latest episodes of the "Sequel"...I'll post them here.

.

.

to be continued

with kind regards

Tamar

The Ford GT LM coming out of the 130R behind the now benched SV8GTE and in front of the ProSpeed C7R

tamar - 6-6-2021 at 16:45

So we'll be racing the Ford again this year @ Le Mans, in just a bit more than 3 weeks..... Time to take stock and clear out the cobwebs.

Because although the Ford has served us well last year with good results, there's always room for improvement.

After the 2019 Le Mans 24hrs we had the following bullit list with attention points.

- Rear Wing kept coming off

- Bit of overweight.

- Lights, Hard to spot the car from the rear specially through Dunlop/'S de la Foret/Tetre Rouge section.

- Motor ran hot: Shorter gearing, Improve cooling,

- 0,75 offset gave to little magnatraction compared to competition (that ran 1,0 offset pods)

- Frontaxle too short, Front axle stuck solid after a crash as right wheel moved in on Axle.

Some of the items on the bullet list have been taken care of and race proven during the rest of the 2019/20 races (like the rubber wingsupports and

the 1,0 offset pod).

Clearing out the cobwebs

So the first thing I did to the Ford after last sunday's test was to give her a good clean up and inspect the body.

No structural damage after one year of racing, few scratches on the nose, striping on the roof showing some wear, no cracks, damage etc etc.

The Bison Tix neoprene glue really worked well and held all parts together. In some area's I had applied it exessively, or just poured it on in a

quick race repair, so I set out to remove some of it.

Tough as hell and still flexible even afyter a year, meaning that with the right amount of applied force...it comes of clean without leaving a mark on

the body.

I cases where the Neoprene glue's bond feels stronger than the part you want to remove it from...a Q-tip dabbed in cleaning petrol will soften the

glue...but...do check if the underlying surface can handle the Cleanig petrol.

On the left the body after clean up, as I wrote a bit overweight...by DISCA 2019 standard, but for Suzuka we actually needed to add 0,7gr balast to

comply with the 2020 rules.

On the right the body with the Z-machine lightkit and interior (carefully) removed. Cleaned and Polished the windows on the inside as lots of tyre

gunk and debris had assembled there.

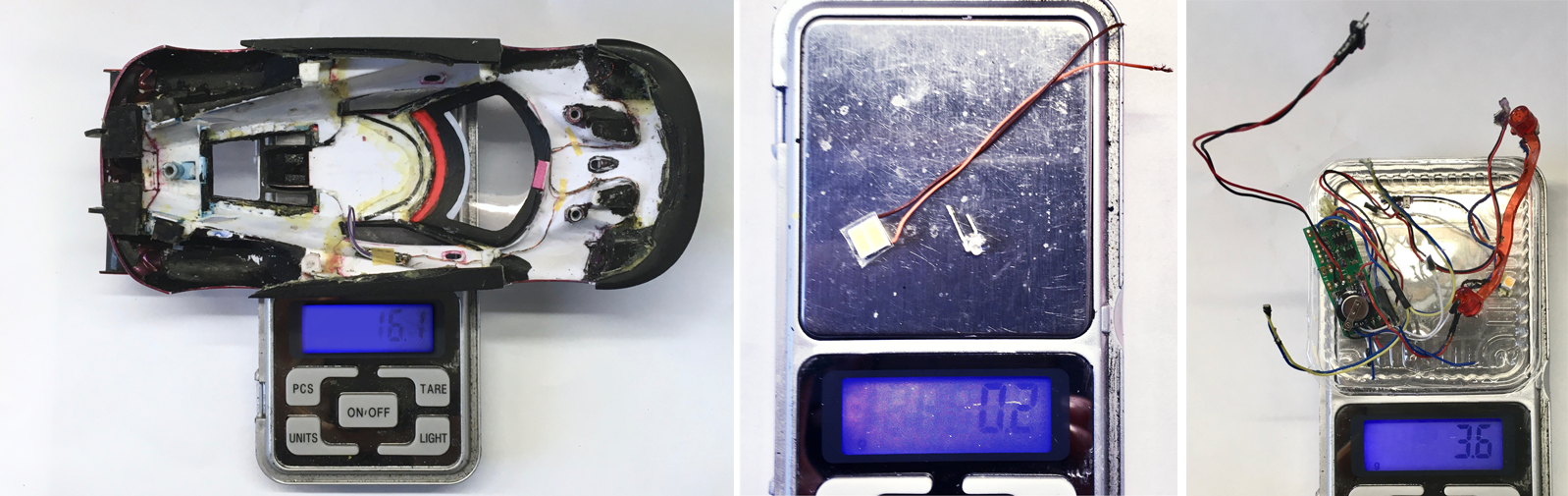

Removing excess glue and a tiny bit of redundant plastic in the roof dropped the body weight by 0,1gr to 16,1gr sans lightkit and interior.

Every bit counts as to address bullit point 2 & 3 well be adding more lights to the body. At lest twice the weight of what's on the scale in the

middle.

So that's at least 0,4 gram we need to find, and on the right scale is the most likely place we might reclaim that weight. Shorter, lighter (and more

flexible) wires and trimming the taillight lenses.

Replacing the capacitor for a lighter version (from slot.it) alone should give us 0,4gr, but need to test if the Z-machine chip will still work with

the lower capacity of the slot.it goldcap. (z-machine 0,33f, Slot.it 0,1f)

Indentification lights, Friend or Foe

Well this the one item where despite our best efforts our Ford seriously lacked "1/32nd realism" because at Le Mans there's no mistaking the Fords

at night.... from any angle.

(here green but identification color for the #68/#18 is red) Our 1/32nd Ford was hard to spot from the rear specially through Dunlop/'S de la

Foret/Tetre Rouge section.

Our aim not to overdo these identification lights (not wanting the disco light set-up as ran by Ditslot in 2018) backfired as the leds we ran were not

visible enough.

So in the picture below you can see the test set-up for the 2020 identification lights. Will mount these high-up underneath the Ford "wings" but

will need to black out the inner surface so the led won't shine trhough the plastic.

The mini Z-machine brake leds give a nice diffuse light.

Actually all Z-machine leds give of diffuse light, while that's good for most lights its not I.m.o. for the headlights.

Although the Ford with its tripple headlights was easilly recognisable from the front...I wanted to have light beams in front of the car.

So instead of the regular "diffuse" smd leds, "old School" 1,8mmø leds with clear lensses (see bottom right) will be mounted in the foglights.

Still working on the wiring plan, the plan is to have the headlights connected to the Z-machine chip fed by the motor wires and feed the foglights

from the O2 chip.

This way I can give the foglights a bit more juice (3v on/off switchable) ...

The O2 chip will also be used to light up the numbershields

Lots of paint

Say what you like off Scalex cars, but their paint jobs are meant to last, 48 hrs of hard racing and hardly a scratch on the Ford...but that needed to

change.

As the only way I would be able to get any light to the numbershields required digging in deep and carefully scratch away the paint.

Did not do this free hand off course, masked of the body around the shield and started scraping away the paint...carefully, layer by layer

As you can see picture right, there were quite a lot of them, The tamponed print, then the dark metallic blue, then a silver layer, then metallic red

and then finally bare white plastic.

So no masking, no extra's, just a bit of elbow grease, two LED's (might spread them further apart) and a paper sticker (decal or vinyl would do the

same job, maybe even better)

More info on the SMD led's I used can be found here:

https://www.slotforum.com/threads/number-lights.194389/#post-2313881

to be continued:

With kind regards

Tamar

tamar - 6-6-2021 at 16:52

This afternoon and with great pain in my heart I have withdrawn the Mission8 team entry for the DiSCA LM 24hrs April 4-6 2020.

Main reason for the withdrawal...the COVID -19 situation.

This has been an unanimous team decision, in full understanding that this would make not only our entry, but also the already paid entry fees null and

void.

We hope that this will compensate for any damages resulting from our late withdrawal.

We have taken this decision while it was still ours to make, we wanted to be Pro active in this situation and not await further developments.

We wish DiSCA and all the other teams and friends all the best in these tasking times. Take care, stay healthy.

with kind regards

Tamar

p.s. Eventhough we've cancelled our trip to Le Mans, this story and post here are still

to be continued

tamar - 6-6-2021 at 17:02

In the mean while, let me share with you some of the work I did under the hood, this was done last week when the go, no go situation on our the road

to Le Mans was going on.

As some of you may remember, we had two chassis prepped for Le Mans last year, the MK 2 with the 1,0 mm offset and the MK2 evo with the 0,75 offset

pod.

We raced the MK2 evo at Le Mans, but switched for the rest of the season to the MK2.

So last week I decided to give the MK2 evo a good once over.

Ford GT LM Prospeed chassis MK2, pictured above just after the 2019 LM24 hrs.

Spend a whole evening to get the MK2 evo chassis to move and float the body like the MK2 does. Made me realise how much work had been done to that

chassis.

When I compared them sitting side by side on my workbench I noticed that every item on the MK2 chassis had been changed in one way or the other.

Minimal differences in height of the body screw posts, chassis edges shave just that tiny bit to clear binding iussues.

Guide ride height, front axle travel, Body supports, suspension travel and springs.

The list of mods I apparently had done...(and forgotten) just kept growing, improving the chassis bit by bit, race by race.

At the end of the evening I still wasn't happy. I'd gotten close...but just not close enough. Something just didn't feel right...

So...back to square one, disassembled the whole chassis and checked it on my chassis flatting plate...and sure enough, there I got confirmation that

the chassis was bend.

Wheter this was caused by running it in the LM 24 or just by handling/assembling it prior to the race...we'll never know, although with my experience

of how the M8 chassis got bend...I assume the latter.

Anyhow, this meant that Chassis MK2 was destined for a bath...and a slow cooldown in the oven.

In the mean while as the now straightened chassis cooled down to room temp, I started adressing items 2 and 4 on the bullit list. (bit of overweight

and improve cooling)

Some of you may have spotted the slot's I cut in the diffuser on the previous chassis image.

Like the M8 diffuser it saves a tiny bit of weight and the slots will help extracting warm air out from under the body.....but there's more to it

that just that.

to be continued:

With kind regards

Tamar

#18

Ford MonkeyTown Team NL, Ford GT LM GTE

#18

Ford MonkeyTown Team NL, Ford GT LM GTE

.

.

.

.